recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:96.9%

- Type:Rubber additive antioxidant

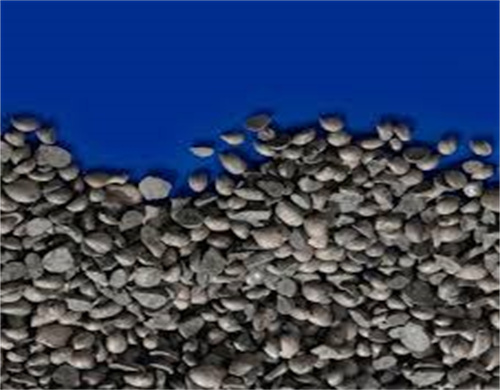

- Appearance:Amber to Brown Granulose

- Ash:0.10% Max

- Application:bicycles births, rubber, plastic

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

rubber antioxidant 4010 (ippd) with best price,Rubber antioxidant 4010 (ippd) chemical name: n-isopropyl-n'-phenyl-p-phenylenediamine. Molecular formula: c15h18n2. It is commonly used in tire manufacturing and can significantly improve the aging resistance and overall performance of rubber, helping to improve durability and safety.

various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

rubber antioxidant ippd(4010na) rubber accelerator

ippd (4010na) rubber antioxidant, a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature.

rubber antioxidant ippd: key additive for industry,learn about rubber antioxidant ippd, its unique properties that enhance aging resistance, market trends, and economic benefits for manufacturers in the rubber industry.

buy wholesale rubber antioxidants in ghana rubber

find the best ghana rubber antioxidants and explore our extensive collection of high-quality rubber antioxidants from ghana. buy wholesale rubber antioxidants in ghana from trusted suppliers.

rubber antioxidant ippd 4010na 101-72-4 manufacturer,rubber antioxidant ippd offers superior protection against oxidative degradation and ozone attack, making it a top choice for manufacturers seeking to improve the performance and durability of their rubber products.

rubber antioxidant ippd: enhancing competitiveness in the

discover how rubber antioxidant ippd enhances the performance and market competitiveness of rubber products by improving aging resistance, economic benefits, and production technology. stay ahead with insights into market trends.

advantages of rubber antioxidant ippd in tropical regions,explore the benefits of rubber antioxidant ippd in enhancing the durability and market competitiveness of rubber products in tropical climates. learn how ippd can extend the service life of rubber and improve product resistance to aging.

comparative analysis of rubber antioxidant ippd and other

explore the comparative analysis of rubber antioxidant ippd (n-isopropyl-n'-phenyl-p-phenylenediamine) with other antioxidants in this comprehensive review. learn about the anti-aging advantages, diverse application fields, and cost-effectiveness of ippd in the rubber manufacturing industry.

rubber antioxidants and chemical 6ppd,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental

- Do antioxidants and their TPS increase environmental risk awareness of rubber products?

- To our knowledge, this is the first review on antioxidants and their TPs in the environment, which may elevate the environmental risk awareness of rubber products and their TPs in the near future.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Does antioxidant 2246 protect rubber from aging?

- Among them, antioxidant 2246 has a good performance to protect rubber from aging caused by heat, oxygen, and metals. Because hydrogen in phenolic antioxidants can combine with the oxygen in air, their antiaging efficiency is therefore lowered compared with amine antioxidants [21, 22].

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.