accelerator cbs (cz) hamiico rubber accelerator products

- Classification:Chemical Auxiliary Agent

- Purity:97%

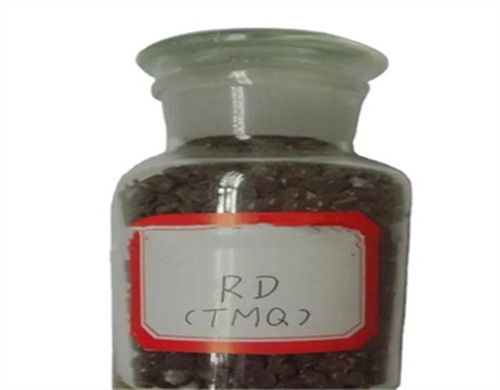

- Type:Rubber additive antioxidant

- Appearance:Grey to Very Dark Grey Solid

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

rubber antioxidant ippd(4010na),while used primarily for ozone resistance, it is a more active antioxidant than quinoline or diphenylamine based antioxidants. the product (alone or in combination with tmq ) provides compound protection against catalytic degradation by copper and other heavy metals.

primary accelerator: this group of accelerators usually have a long burning time and are quickly cooked in the main stage of vulcanization polymer accelerators are used to produce various types of rubber such as isoprene, styrene, butadiene and nbr.

best rubber antioxidant ippd/4010na for tyre

product name: rubber antioxidant ippd cas no.: 101-72-4 mf: c15h18n2 einecs no.: 202-969-7 appearance,rubber accelerator rubber antioxidant vulcanizing agent plastics auxiliary others functional solvent menu no results inquiry email whatapp.

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

recent progress in the rubber antioxidants price

in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rubber antioxidant ippd phenylenedia- mine antidegradants,prüfen und messen testing and measuring www.kgk-rubberpoint.de kgk · 4 2021 39 rubber compounds · nmr · spectroscopy · rubber antioxidant ippd phenylenedia-mine antidegradants · aging of rubber all organic polymers like rubbers with

the best china ippd, rubber antioxidant in india widely used hot sale

rubber antioxidant ippd (4010 na) supple rubber it disperses readily in rubber and resists degradation of rubber by heavy metal contaminations too. typical dosage varies from 0.5 3.0 phr depending upon the usage conditions. we import this material from

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

rubber antioxidant 6ppd ippd tmq rubber accelerator rubber

rubber chemical supplier for more than 30 years we produce rubber accelerator and antioxidants, and are committed to being one of the most reliable suppliers in global rubber industry about zarc Antioxidant IPPD Chemical Auxiliary Agent for Rubber Tyre it is a private enterprise that specializes in manufacturing and distributing rubber chemicals.. zarc is located in national industrial.

N(1,3-dimethyl-butyl)-N'-phenyl-P-phenylenediamine chemical active antioxidant,infobox references. n-isopropyl-n′-phenyl-1,4-phenylenediamine (often abbreviated ippd) is an organic compound commonly used as an antiozonant in rubbers. [1] like other p-phenylenediamine -based antiozonants it works by virtue of its low ionization energy, which allows it to react with ozone faster than ozone will react with rubber. [2]

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- How many rubber antioxidants are produced in China?

- China is one of the main countries producing rubber antioxidants, and the production accounts for more than 70% of the total amount globally. The production of rubber antioxidants in China ranged from 365,000 to 378,000 tons during 2016–2020, showing a constant annual trend .

- Do antioxidants influence vulcanization properties of natural rubber compound?

- Study the influence of high concentrations of antioxidants N-isopropyl-N-phenyl-p-phenylenediamine (IPPD) and 2,2,4-trimethyl-1,2-dihydroquinoline (TMQ) and the mixing time of the vulcanization physical properties, thermal properties, mechanical properties and structure micro on natural rubber compound has been done.