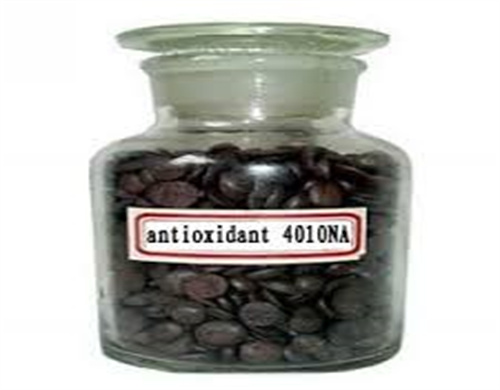

rubber antioxidant 4010 (ippd) exporter

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Rubber additive antioxidant

- Appearance:Purple brown to dark brown granules or flakes

- Softening point:80-100℃

- Application:Used in Tires,Industrial Rubber Products

- Storage:Store in a Cool, Dry Place

- Package:Ply Kraft Paper Bag

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

it is an antioxidant with high efficiency and multi-functions, being used in a wide range of applications. it is applicable in natural rubber, many kinds of synthetic rubber products and their latexes. it can be used in airplane, car tyre, bicycle tyre, as well as rubber products and latexes in cable industry.

rubber antioxidants tmq particles mdpi

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

4010na rubber antioxidant: enhancing durability and,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential considerations for commercial procurement. what is 4010na? 4010na, also known as.

rubber antioxidant 4010na(ippd) with high quality

generic family: additive -- antioxidant / heat stabilizer supplied. properties: a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

synergistic effects of antioxidant and silica on enhancing,firstly, the incorporation of silica was capable of improving oxygen (o 2) barrier ability of nr and inhibiting the migration of 4010na. secondly, antioxidant 4010na could be prior to terminate peroxy radicals, and its addition enabled 4010na/sio 2 /nr composite to be of an appropriately high cross-linking density due to a vulcanization.

rubber antioxidant ippd(4010na) manufacture

properties: a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds. while used primarily for ozone resistance, it is a more active antioxidant than quinoline or diphenylamine based antioxidants.

recent progress in the rubber antioxidants price,this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. the oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism [1]. as shown in fig. This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

ippd antioxidant 4010na N-isopropyl-N'-phenyl-p-phenylenediamine

the normal dosage in natural rubber is about 2.5~3.0 parts, and less than 4 parts in styrene butadiene rubber. it can also be used as the thermal and oxygen stabilizer in polyethylene, polypropylene and acrylic resin. use: industrial antioxidants have been used to protect rubber and plastic goods from thermal oxidation.

rubber antioxidant ippd 4010na 101-72-4 bastone,rubber antioxidant ippd is compatible with a range of rubber polymers, including natural rubber, synthetic rubber, and latex. it can be easily incorporated into rubber formulations using standard mixing equipment, and has a low processing temperature, making it ideal for large-scale manufacturing.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Can rubber antioxidants contain rare-earth ions?

- The recently reported rubber antioxidants containing rare-earth ions are summarized in Fig. 4, for instance, Sun et al. prepared a novel hindered phenol rare-earth complex (DTSm) (Fig. 4 f) by a simple and green method using 3,5-di-tert-butyl-4-hydroxybenzoic acid (DT) and samarium chloride hexahydrate (SmCl 3 ·6H 2 O) via coordination reaction.