rubber antioxidant ippd(4010na) rubber accelerator

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Antioxidant

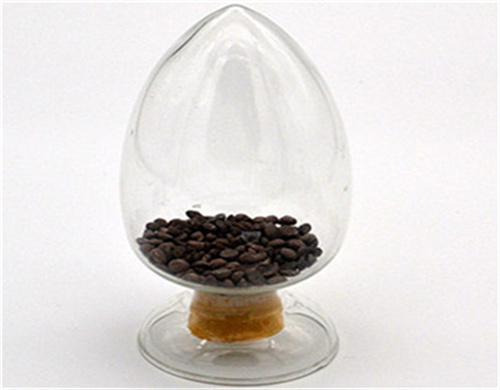

- Appearance:Dark brown to dark vilet pastilles or flake

- Content:95%

- Application:Shoe Soles, auto tyre

- Production Capacity:3000 Ton/Year

- Package:25kg/drum

rubber antioxidant 4010na( ippd) price,rubber antioxidant 4010na( ippd) generic family: additive -- antioxidant / heat stabilizer; IPPD is used for natural rubber and synthetic rubbers such as styrenebutadiene rubber, cisbutadiene rubber, and nitrile rubber. it is an antioxidant used for rubber products with high efficiency, low poison and low solvent-extraction amout.

ippd (4010na) rubber antioxidant, a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature.

rubber antioxidant 4010 (ippd) with best price

packed in kraft paper bags of 25kgs net each with p.e. liner inside, or jumbo bags. 12mt per 20’gp, 24mt per 40’gp, palletized. shipping marks: neutral export standard. also can be customized. storage validity: 12 months. get the specification: msds 4010na granule.

4010na rubber antioxidant: enhancing durability,what is 4010na? 4010na, also known as ippd (n-isopropyl-n'-phenyl-p-phenylenediamine), is a synthetic rubber antioxidant belonging to the class of amine antioxidants. it is an effective inhibitor of oxidation, preventing the degradation of rubber by oxidative processes.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

rubber antioxidant 4010na(ippd) price,rubber antioxidant 4010na (ippd) a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

rubber antioxidant ippd 4010na high quality rubber

rubber andioxidant- ippd (4010na) a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

rubber antioxidant ippd 4010na 101-72-4 manufacturer,rubber antioxidant ippd offers superior protection against oxidative degradation and ozone attack, making it a top choice for manufacturers seeking to improve the performance and durability of their rubber products.

source rubber antioxidant ippd(4010na) high quality rubber

rubber antioxidant 4010na (ippd) 4010na is a comprehensive and efficient rubber antioxidant, it has good protection against ozone aging, metal aging and resistance to flexing, fatigue and cracking; suitable for the rubber products working under static, dynamic or intermittent conditions; low melting point and easy to disperse, the solubility in

rubber antioxidant ippd/4010na global trade leader ecrobot,commodity name: rubber antioxidant 4010na (ippd) chemical name: n-isopropyl-n'-phenyl-p-phenylenediamine chemical structure: application: mainly used in manufacture of tires, rubber shoes and other technical goods quality standard: (gb8828-2003) cas no.:101-72-4 specification: appearance: dark brown to dark violet pastilles; melting point : 70.0℃ min heating loss : 0.30% max ash : 0.30% max

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Does a sustained release of EAB improve anti-oxidative capacity of rubber composites?

- Moreover, the retention of EAB for SBR/Loaded HNTs is about 50% higher than for SBR/HNTs and CDs after the thermo-aging testing, demonstrating the sustained release of CDs from HNTs could enhance the anti-oxidative capacity of the rubber composites.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.