rubber anti-aging agent 6ppd and its ozonation product 6ppdq

- Classification:Chemical Auxiliary Agent

- Purity:98.9%

- Type:Rubber antioxidant

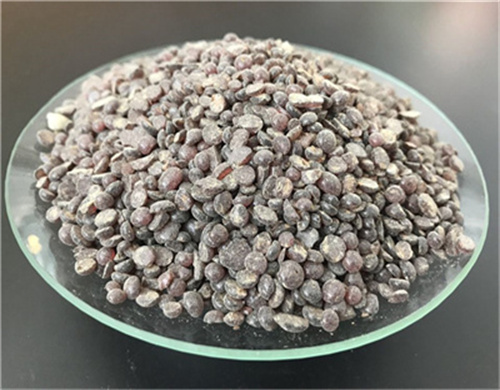

- Appearance:Dark purple pastilles

- Ash:0.10% Max

- Application:bicycles births, rubber, plastic

- Storage:Dry

- Package:1kg/polybag, 25kg/kraftbag

4010na rubber antioxidant: enhancing durability and,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential considerations for commercial procurement. what is 4010na? 4010na, also known as.

rubber anti-aging agent 6ppd and its ozonation product 6ppdq: environmental distribution and biological toxicity li jia-yao, shen hui-min, xu ting-ting, guo ying guangdong key laboratory of environmental pollution and health, school of environment, jinan university, guangzhou 510632, china

china anti-scorch agent yg-1 suppliers, company cost

product name :rubber antiscorching agent yg-1. use : this product can prevent early vulcanization of rubber. suitable for sulfur-vulcanized natural rubber, butadiene rubber, styrene butadiene rubber, nitrile butadiene rubber, and combined rubber, as a scorch retarder for the rubber compound, and is excellent for the combined rubber compound of m, dm, imtd and nobs the anti-scorching effect.

antioxidant 4010na-zhejiang zhedong rubber auxiliary,details. executive standard: gb/t 8828-2003. [performance] natural rubber, synthetic rubber and latex with excellent general antioxidant, excellent protective properties of ozone cracking; also the heat, oxygen, light and aging two protective agent. this product can also be used independently, but also with paraffin wax or other antioxidant and.

synergistic effects of antioxidant and silica on enhancing

however, in aging experiments, the anti-oxidative efficacies of 4010na in 4010na/nr or 4010na/cb/nr composite are inferior to that in 4010na/sio 2 /nr composite (based on the difference of carbonyl increase rate r with and without 4010na in table 3). in our opinion, this phenomenon is associated with the physical loss (or migration) of antioxidant.

rubber antioxidants anti-aging agent 6ppd (4020) ippd (4010na,rubber antioxidants anti-aging agent 6ppd (4020) ippd (4010na) tmq (rd), find details and price about rubber chemical 6ppd from rubber antioxidants anti-aging agent 6ppd (4020) ippd (4010na) tmq (rd) kitamura-xia(shanghai)co.ltd.

introduction of rubber antiaging agent and its types

there are anti-aging agent ndbc, anti-aging agent ndibc, anti-aging agent ndmc. all green powder. with good ozone resistance and thermal oxidation resistance, expensive (due to nickel on the earth less storage, but a wide range of uses), but also a certain toxicity, deep color, easy to spray frost, not suitable for light color rubber products.

rubber antiaging agent ippd (4010na) b2brazil,antiaging agent ippd is an additive, for natural rubber, synthetic rubber and latex universal excellent anti-aging agent, ozone, flexural cracking protection performance is good, but also heat, oxygen...

antioxidant dtpd high efficient rubber antioxidant

it is high efficient anti-aging agent in tyre industry and can also be applied to various rubber products. antioxidant dtpd(3100) is with good long-term performance especially when it is combined with anti-aging agent 4020 or 4010nal : l, which is the best ozone resistance system to improve lifespan of the tyre.

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- What causes oxidative aging of rubber?

- Various external factors, including oxidative agents (such as oxygen), heavy metals, UV rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. This review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

- What happens if rubber ages?

- Rubbers, especially the diene-rubbers containing double bonds in their main chains, are particularly susceptible to aging, leading to the deterioration of the outlook, hardness, and physical/mechanical performances. The aging of the rubber would even lead to a great waste of rubber resources and threaten people's lives and safety.