recent progress in the rubber antioxidants Rubber Auxiliary Agent

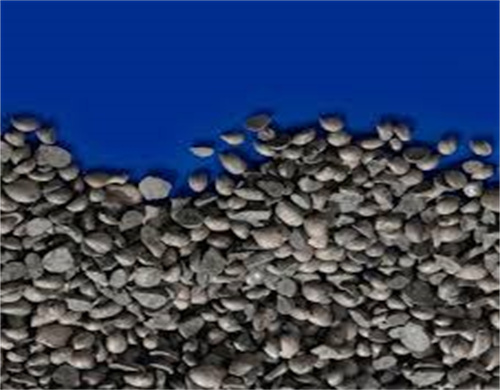

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Rubber chemicals

- Appearance:Grey purple to purple brown pastilles

- Ash Content:0.20%

- Application:tyres, motorcycles births

- Production Capacity:1000 Metric Tons per Month

- Package:20kg kraft bags,500kgs/pallet

efficient, sustainable materials for tires high performance,preparation silica reinforced pdbii and silica reinforced pdbib composites for green tire. poly(di- n -butyl itaconate- co -isoprene) (pdbii) was mixed with polybutadiene (br), colored with phthalocyanine to form silica/pdbii composites according to the formulation shown in table s4a.

the rubber antioxidant market is expected to expand significantly in the future due to the increasing demand for antioxidants in the manufacture of various rubber products used in the tire industry, automotive industry, and others.

rubber antioxidants and their transformation products

n-(1,3-dimethylbutyl)-n0-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles...

(pdf) rubber antioxidants and their transformation products,in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing...

synthesis and properties of a novel reactive and low

rubber composites containing antioxidants 4020 and 4010na were immersed and extracted, resulting in solutions that were noticeably darker in color than those of the rubber composites with gma-ppda antioxidants, which had also been immersed.

rubber antioxidants and chemical 6ppd,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

enhancing tire durability: application analysis of rubber

this article focuses on the application of rubber antioxidant 6ppd (4020) in improving tire durability, revealing its specific mechanism of antioxidant and anti-aging, as well as its significant effects in practical applications.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

after 168 hours of thermal oxidative aging test at 100℃, styrene‐butadiene rubber with 10 wt % surface thiol functionalized mesoporous silica nanorods loaded with 4020 (msn‐sh‐4020)...

(pdf) rubber antioxidants and their transformation products,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)-n′ -phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.