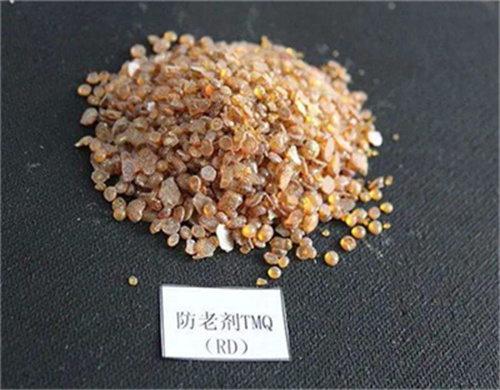

rubber chemicals antioxidant 4010na Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Anti-aging agent

- Appearance:Purple brown to dark brown granules or flakes

- Shelf life:2 Years

- Application:Plastic Auxiliary Agents

- Storage:Store in a Cool, Dry Place

- Package:Ply Kraft Paper Bag

effectiveness of different kinds of antioxidants in resin,the effectiveness of several antioxidants belonging to different chemical classes such as p-phenylene diamine (antioxidant 4010na), secondary amine (antioxidant 445), quinoline (antioxidant rd), and phenolic (bht, 1010, 2246) on the performance of a resin-cured biir vulcanizate was investigated.

various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

synergistic effects of antioxidant and silica on enhancing

in this work, the thermo-oxidative aging performance of antioxidant n-isopropylN'-phenyl-p-phenylenediamine (4010na)/silica (sio 2)/natural rubber (nr) composite was evaluated by the variations of mechanical properties and chemical structure after aging at 100 ℃.

comparison effects of lanthanum stearate and antioxidants for sale,this work studied possibilities of using lanthanum stearate (last) as an antioxidant in epoxidized natural rubber containing 25 mol.% expoxidation (enr25) compounds. for comparison purposes, two commercial antioxidant 4010na and mb were also used.

the msd curves of 4010na and go-4010na in nbr composites

antioxidant 4010na was successfully grafted onto graphene oxide (go) to prepare an anti-migration antioxidant (go-4010n... similar publications. synthesis and performance of two ecofriendly...

highly aging-resistant elastomers doped with antioxidant,a novel aging-resistant styrene–butadiene rubber (sbr) composite is prepared using the antioxidant n-isopropylN'-phenyl-p-phenylenediamine (4010na) loaded inside of halloysite clay nanotubes and u...

synthesis and properties of a novel reactive and low

through a two-step synthesis process, lu developed a reactive antioxidant, napm, added it to natural rubber, and discovered that its aging resistance was superior to those of 4010na and 4020. zhao et al. (16) grafted the antioxidant intermediate rt onto the surface of lignin and created a hybrid modified lignin-based filled antioxidant named

synergistic effects of antioxidant and silica on enhancing,in this work, the thermo-oxidative aging performance of antioxidant n-isopropylN'-phenyl-p-phenylenediamine (4010na)/silica (sio2)/natural rubber (nr) composite was evaluated by the...

synthesis and properties of a novel reactive and low

rubber composites containing antioxidants 4020 and 4010na were immersed and extracted, resulting in solutions that were noticeably darker in color than those of the rubber composites with gma-ppda antioxidants, which had also been immersed.

4010na rubber antioxidant: enhancing durability,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential cons

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Are carbon dots a rubber antioxidant?

- Carbon dots as rubber antioxidants The carbon materials, such as carbon black, graphene, fullerene, etc, are well known to be able to retard the aging processes of various polymers including polyolefine, rubber, polyamide, etc., due to the active trapping of radicals .

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.