wholesale rubber antioxidant ippd(4010 na) in india widely used hot

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber additive antioxidant

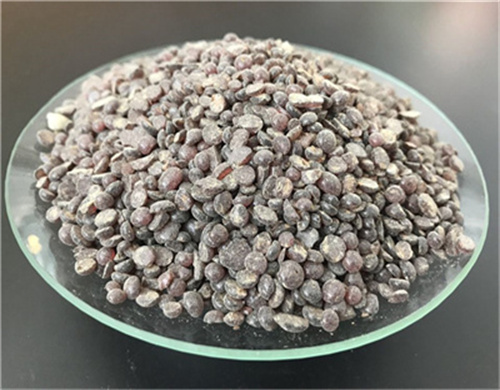

- Appearance:Light brown or white powder or granule

- Melting point:45-46°C

- Application:For nitrilebutylbenzene

- Production Capacity:5000 Ton/Tons per Month

- Package:25kg/barrel

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

best quality antioxidant rubber antioxidant 4010 rubber 4010 antioxidant agent, 4010 antioxidant agent. best price rubber antioxidant 4010 na ippd in the world us $ 2300-2800 / ton 0.5 tons (min. order),It is also used in the production of plastics, paints, and other industrial applications. send

the best china ippd, rubber antioxidant in india widely used hot sale

you can also choose from free samples. there are 383 rubber antioxidant 4010na ippd suppliers, mainly located in asia. the top supplying country or region is china, which supply 100% of rubber antioxidant 4010na ippd respectively. rubber antioxidant 4010na

investigation of the compatibility and damping performance of graphene,rubber damping materials are widely used in electronics, electrical and other fields because of their unique viscoelasticity. how to prepare high-damping materials and prevent small molecule migration has attracted much attention. antioxidant 4010na was successfully grafted onto graphene oxide (go) to prepare an anti-migration antioxidant (go-4010na). a combined molecular dynamics (md.

synergistic effects of antioxidant 4010na ippd

although there are a variety of industrial antioxidants on the market at present, n, n′-substituted p-phenylenediamines are one of the most widely used as antioxidants in rubber industry [28].some studies about anti-oxidation activity of n, n′-substituted p-phenylenediamines have been reported, nevertheless, most of the papers evaluated their anti-oxidation activity by experimental methods.

investigation of the compatibility and damping performance of graphene,rubber damping materials are widely used in electronics, electrical and other fields because of their unique viscoelasticity. how to prepare high-damping materials and prevent small molecule migration has attracted much attention. antioxidant 4010na was.

investigation of the compatibility and damping performance of graphene

in this study, antioxidant n-isopropyl-n’-phenyl-p-phenylenediamine (4010na) was selected as a damping additive. nbr was selected as a polar rubber matrix. small molecule 4010na contains imino, which is easy to form h-bonds with nbr. firstly, antioxidant

recent progress in the rubber antioxidants price,this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. the oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism [1]. as shown in fig. This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

rubber antioxidant 4010na(ippd) with really good price

access the complete datasheet details for rubber antioxidant 4010na(ippd) when you create your free account with prospector. you’ll find complete information on physical, mechanical and hardness specs. material status commercial: active documents.

4010na rubber antioxidant: enhancing durability and performance,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential considerations for commercial procurement. what is 4010na? 4010na, also known as.

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.