recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Antioxidant

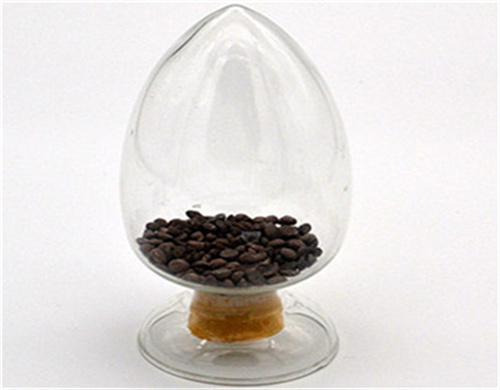

- Appearance:Dark purple granule

- Density:1.08g/cm3

- Application:Used in Tires,Industrial Rubber Products

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

4010na rubber antioxidant: enhancing durability,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential cons

various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

rubber antioxidant ippd(4010na) rubber accelerator

ippd (4010na) rubber antioxidant, a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature.

rubber antioxidants and chemical 6ppd,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental

synergistic effects of antioxidant and silica on enhancing

in this work, the thermo-oxidative aging performance of antioxidant n-isopropyl- n ′-phenyl- p -phenylenediamine (4010na)/silica (sio 2)/natural rubber (nr) composite was evaluated by the variations of mechanical properties and chemical structure after aging at 100 ℃.

rubber antioxidant development rubber-accelerator.com,from the development trend of the world rubber antioxidant, some foreign multinational companies have already begun to adjust production layout, reduce production and distribution, improve the production capacity of a single set of device to improve the overall scale of production to achieve economies of scale, china's dominant antioxidant

high quality rubber antioxidants 4010na ippd

how to prepare high-damping materials and prevent small molecule migration has attracted much attention. antioxidant 4010na was successfully grafted onto graphene oxide (go) to prepare an anti-migration antioxidant (go-4010na).

rubber antioxidant 4010 (ippd) with best price,Rubber antioxidant 4010 (ippd) chemical name: n-isopropyl-n'-phenyl-p-phenylenediamine. Molecular formula: c15h18n2. It is commonly used in tire manufacturing and can significantly improve the aging resistance and overall performance of rubber, helping to improve durability and safety.

widely used antioxidant rd rubber for indonesia africana.be

rubber accelerator dm. this product is a kind of natural rubber, synthetic rubber and regenerated adhesive. the vulcanized rubber has good aging resistance, but the products in contact with the vulcanized rubber easily have bitter taste, so it is not suitable for rubber products in contact with food.

rubber antioxidant 4010na(ippd) price,rubber antioxidant 4010na (ippd) a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.

- What is thermo-oxidative aging of rubber?

- This review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. The oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism . As shown in Fig. 1a, rubber aging processes have three distinct phases: (i) Initiation, (ii) Propagation, and

- Can rubber antioxidants contain rare-earth ions?

- The recently reported rubber antioxidants containing rare-earth ions are summarized in Fig. 4, for instance, Sun et al. prepared a novel hindered phenol rare-earth complex (DTSm) (Fig. 4 f) by a simple and green method using 3,5-di-tert-butyl-4-hydroxybenzoic acid (DT) and samarium chloride hexahydrate (SmCl 3 ·6H 2 O) via coordination reaction.