rubber antioxidant 4010 (ippd) with best price

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Rubber additive antioxidant

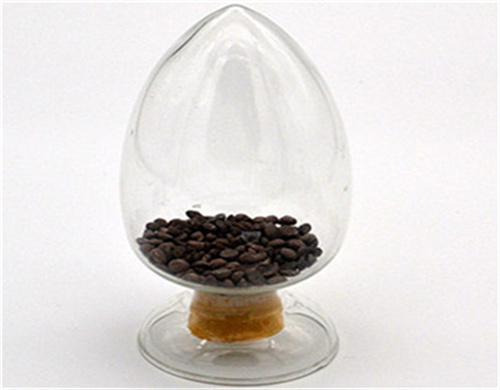

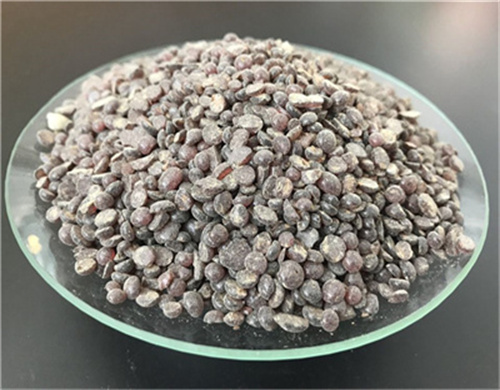

- Appearance:Gray Purple or Purple Brown Granular

- Certificate:COA, MSDS, TDS

- Application:Paper Chemicals, Rubber Auxiliary Agents

- Storage:Store in a Cool, Dry Place

- Package:Ply Kraft Paper Bag

rubber antioxidant 4010na( ippd) price,rubber antioxidant 4010na( ippd) generic family: additive -- antioxidant / heat stabilizer; IPPD is used for natural rubber and synthetic rubbers such as styrenebutadiene rubber, cisbutadiene rubber, and nitrile rubber. it is an antioxidant used for rubber products with high efficiency, low poison and low solvent-extraction amout.

Rubber antioxidant 4010 (ippd) chemical name: n-isopropyl-n'-phenyl-p-phenylenediamine. Molecular formula: c15h18n2. It is commonly used in tire manufacturing and can significantly improve the aging resistance and overall performance of rubber, helping to improve durability and safety.

rubber antioxidant 4010na(ippd) price

rubber antioxidant 4010na (ippd) a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

antioxidant 4010na (ippd) chemical factory,antioxidant 4010na (ippd) by chemical factory acts as an antioxidant. it is n-isopropyl-n'-phenyl-p-phenylenediamine. it is highly efficient and can be easily oxidized and discolored on the exposure to air and light. antioxidant 4010na (ippd) is recommended for use in latex, natural and synthetic rubber.

synergistic effects of antioxidant and silica on enhancing

in this work, the thermo-oxidative aging performance of antioxidant n-isopropyl- n ′-phenyl- p -phenylenediamine (4010na)/silica (sio 2)/natural rubber (nr) composite was evaluated by the variations of mechanical properties and chemical structure after aging at 100 ℃.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

rubber antioxidant ippd(4010na) products chemical

application: as antioxidant used in plastic, resins and rubber production, especially for natural rubber, many kinds of synthetic rubber products and their latexes. packing storage: 25kg n.w./bag, in plastic fabric laminated kraft bags lined with plastic bags.

rubber antioxidant ippd(4010na) rubber accelerator,properties: a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

rubber antioxidant ippd (4010na) chemical antioxidant

while used primarily for ozone resistance, it is a more active antioxidant than quinoline or diphenylamine based antioxidants. the product (alone or in combination with tmq) provides compound protection against catalytic degradation by copper and other heavy metals.

4010na rubber antioxidant: enhancing durability,4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential cons

- Can rubber antioxidants contain rare-earth ions?

- The recently reported rubber antioxidants containing rare-earth ions are summarized in Fig. 4, for instance, Sun et al. prepared a novel hindered phenol rare-earth complex (DTSm) (Fig. 4 f) by a simple and green method using 3,5-di-tert-butyl-4-hydroxybenzoic acid (DT) and samarium chloride hexahydrate (SmCl 3 ·6H 2 O) via coordination reaction.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.