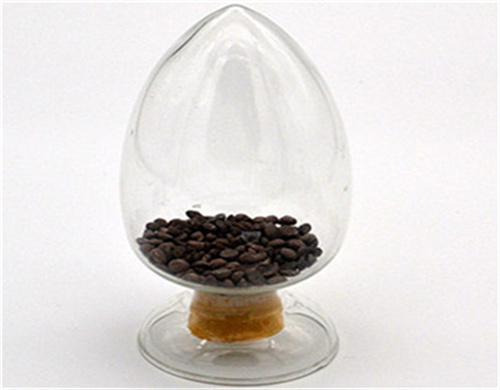

rubber antioxidant tmq with best price

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Rubber chemicals

- Appearance:Dark brown to dark vilet pastilles or flake

- Feature:Chemical Resistance

- Application:Natural Rubber, Synthetic Rubber Common Use

- Production Capacity:50000000t/Year

- Package:25 kg plastic woven bag

performance characteristics of rubber additives and its,anti-aging agent aw can prevent the cracking of rubber products caused by ozone. it is especially suitable for rubber products used under dynamic conditions. used in combination with anti-aging agents h, d and 4010, it can enhance its effectiveness.

rd is an excellent kind of general-purpose ammonia anti-aging agent. it is particular suit to full-steel, semi-steel radial tyre. also apply to many kinds of tires, rubber tubes, gummed tape rubber overshoes and general industrial rubber products. suits to emulsion products too.

tmq antioxidant for rubber industry: enhancing performance

tmq, the antioxidant rd, is a vital additive in the rubber industry, safeguarding rubber products from premature aging and degradation. with its exceptional antioxidative properties, tmq enhances the durability, heat resistance, and flexibility retention of rubber compounds.

application of antioxidant dtpd/3100 in rubber industry,dtpd is suitable for natural rubber and various synthetic rubbers, such as styrene-butadiene rubber (sbr), butadiene rubber (br), chloroprene rubber (cr), etc. it can play an anti-aging role in various rubber products, including tires, hoses, seals, wires and cables, soles, etc.

oil-resistant low-temperature-resistant modified nitrile

the oil-resistant low-temperature-resistant modified nitrile butadiene rubber according to claim 1, characterized in that: the anti-aging agent comprises an anti-aging agent rd and an...

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

the power of antioxidant agent rd(tmq) for sale

rd, also known as tmq, is a powerful antioxidant agent that plays a vital role in enhancing the durability and longevity of rubber products. let's delve into the world of antioxidant agent rd(tmq) to grasp its significance, versatility, and profound impact on rubber-based applications.

classification and development status of rubber antioxidants,anti-aging agent aw can prevent rubber products from cracking caused by ozone, and is particularly suitable for rubber product compounds used under dynamic conditions. when used in...

3 minutes to read the anti-aging agent, tmq, 6ppd, ippd

a general-purpose anti-aging agent for natural rubber and synthetic rubber latex. it has excellent protection against ozone cracking and flex cracking; it is also an excellent protective agent for heat, oxygen, light and general aging.

rubber antioxidant tmq for sale products,antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

- Are rubber antioxidants effective against aging and antimigration?

- The antiaging and antimigration properties of the rubber antioxidants were enhanced without damaging the mechanical properties of the rubber matrix. The short-term and long-term antiaging and antimigration properties of this antioxidant are superior to those of commercially available antioxidants. CC-BY-NC-ND 4.0 . 1. Introduction

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- What is the aging time of rubber?

- The aging time was 3 days. The relative contents of the rubber surface elements were measured using XPS. The table shows the relative contents of the surface nitrogen elements in the three groups of samples before and after aging.

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.