rubber antioxidant tmq (rd) 26780-96-1 manufacturer

- Classification:Chemical Auxiliary Agent

- Purity:96.0% MIN

- Type:Rubber chemicals

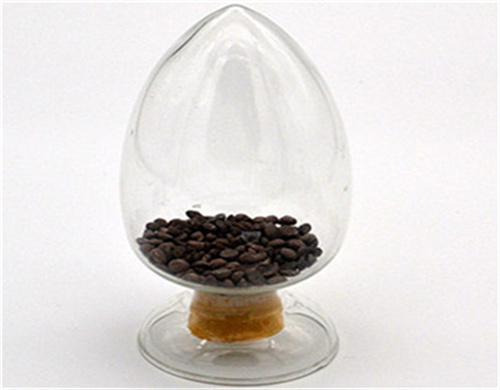

- Appearance:Dark brown, dark violet pellet

- Place of Origin:Henan, China

- Application:Rubber Industry

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

with its exceptional oxidation resistance, rubber antioxidant tmq is ideal for prolonging the lifespan of rubber products such as tires, rubber tubes, and cables. it protects against cracking, breaking, and becoming brittle, even in high-temperature and high-humidity conditions.

rubber antioxidant tmq for sale products

antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

nurvinox h-tmq rubber antioxidant nanjing union rubber,primary antioxidant in dry rubber application to maintain physical and surface. properties with good color, excellent anti-scorch, and good heat resistance. at low concentrations. high purity tmq manufactured by controlling the reaction and process to concentrate.

technical data sheet (tds) with high quality

application: tmq (rd) is a very important rubber antioxidant. it is suit to all-steel, semi-steel radial tire and widely used in the manufacture of tires, rubber tube, adhesive tape, wires, cables and other industrial rubber products. package: net weight: 25kg/bag, packed in paper bag lined with plastic bag.

rubber antioxidants: tmq, 6ppd, ippd chemical products,tmq, also known as polymerized 2,2,4-trimethyl-1,2-dihydroquinoline, is a widely used rubber antioxidant. it provides excellent protection against heat, oxygen, and flex-cracking, enhancing the durability and performance of rubber products.

analysis of rubber antioxidant tmq (rd) in different rubber

this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

rubber antioxidants crossland chemicals,ippd is suitable for the formulations of natural rubber and synthetic rubber, as well as for conveyor belts, rubber tubes, cables, etc., rubber products that need dynamic and static oxidation and ozone resistance protection. ippd can be applied to rubber products with lower requirements for discoloration.

rubber antioxidant tmq with best price

rd is an excellent kind of general-purpose ammonia anti-aging agent. it is particular suit to full-steel, semi-steel radial tyre. also apply to many kinds of tires, rubber tubes, gummed tape rubber overshoes and general industrial rubber products. suits to emulsion products too. package:

tmq antioxidant for rubber industry: enhancing performance,tmq, the antioxidant rd, is a vital additive in the rubber industry, safeguarding rubber products from premature aging and degradation. with its exceptional antioxidative properties, tmq enhances the durability, heat resistance, and flexibility retention of rubber compounds.

- What is antioxidant TMQ?

- Antioxidant TMQ is a widely used antioxidant, especially used in the rubber industry. Similar to other antioxidants, TMQ acts as an anti-aging agent and protects rubber from heat and heat. Antioxidants are substances that hinder oxidation. Antioxidants play a role in protecting the polymer from degradation during the production of rubber.

- What is TMQ used for?

- It is widely used as a stabilizer and antioxidant in the rubber industry. TMQ acts as a protective agent against oxidative degradation, which occurs due to heat, oxygen, and other environmental factors. Its primary function is to inhibit the formation of harmful free radicals, thereby extending the service life of rubber products.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.