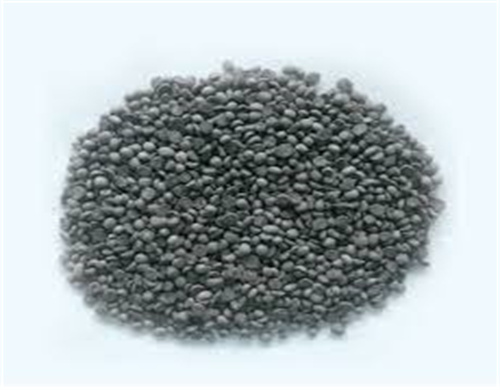

Factory Hot Sale Rubber antioxidant In Stock

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Anti-aging agent

- Appearance:Dark purple granule

- Flash point:204°C

- Application:Rubber goods/plastic/shoes/tyre

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

novel antioxidants based on polymerized 2,2,4-trimethyl-1,2,due to the strong antioxidant activity of hydrazide, 1,3,4-oxadiazoles and 1,2,4-triazoles, our goal is to study the chemical modification of tmq (commercial antioxidant for rubber) by insertion of hydrazide, 1,3,4-oxadiazole and 1,2,4-triazole moieties to its backbone.

in this study, we chose natural rubber (nr) as a matrix and provided a screening strategy based on diverse natural phenolic antioxidants to evaluate their ability in protecting nr composites. thymol, a-tocopherol, and lipid-soluble epigallocatechin gallate (lsegcg) were chosen from 18 natural phenolic antioxidants as potential alternative

recent progress in the rubber antioxidants Rubber Auxiliary Agent

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

effect of antioxidants on aging of the chloroprene rubber,rubber composite is produced from natural rubber (nr), chloroprene rubber (cr), and its blend (cr/nr). the experimental research aimed to study the effect of cr/nr ratio on rubber composite...

rubber antioxidant tmq for sale products

antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

tmq antioxidant for rubber industry: enhancing performance,tmq, the antioxidant rd, is a vital additive in the rubber industry, safeguarding rubber products from premature aging and degradation. with its exceptional antioxidative properties, tmq enhances the durability, heat resistance, and flexibility retention of rubber compounds.

rubber antioxidants and their transformation products

amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

the effect of addition of antioxidant 1,2-dihydro-2,2,4,this study aims to determine the effect of the addition of antioxidants 1,2-dihydro-2,2,4-trimethyl-quinoline (tmq) on natural rubber modified asphalt crepe rubber and its performance in short-term and long-term aging conditions.

analysis on the application of rubber antioxidant tmq (rd) for sale

this paper discusses the application of rubber antioxidant tmq (rd) in various rubber products such as all-steel and semi-steel radial tires, hoses and belts, and its advantages, demonstrating its excellent anti-aging ability.

rubber antioxidants and chemical 6ppd,amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

- Can Antioxidants improve natural rubber modified asphalt crepe rubber performance?

- One method to overcome this problem is the addition of antioxidants. This study aims to determine the effect of the addition of antioxidants 1,2-dihydro-2,2,4-trimethyl-quinoline (TMQ) on natural rubber modified asphalt crepe rubber and its performance in short-term and long-term aging conditions.

- Can polymerized TMQ reduce rubber oxidation?

- The addition of polymerizable antioxidants is one of the most preferable methods to overcome rubber oxidation [14, 15]. One of the mostly used antioxidants is polymerized TMQ. It is a secondary amine and can strongly inhibit the oxidation reactions of rubber [16, 17, 18].

- What is the role of TMQ in rubber product manufacturing?

- Role in Rubber Product Manufacturing: TMQ plays a pivotal role in various stages of rubber product manufacturing, offering a range of benefits to manufacturers: Oxidation Resistance: TMQ effectively inhibits the oxidation process, protecting rubber products from premature aging and degradation caused by exposure to heat, light, and oxygen.

- What are TMQ polymers?

- TMQ is chemically modified to obtain new derivatives, namely; Ester, Hydarzide, Oxadiazole and Triazole. The synthesized polymers are characterized by Fourier transforms infrared spectroscopy (FTIR) and proton-nuclear magnetic resonance (1 HNMR). The formed polymers are evaluated as antioxidants for styrene-butadiene rubber (SBR) composites.