recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

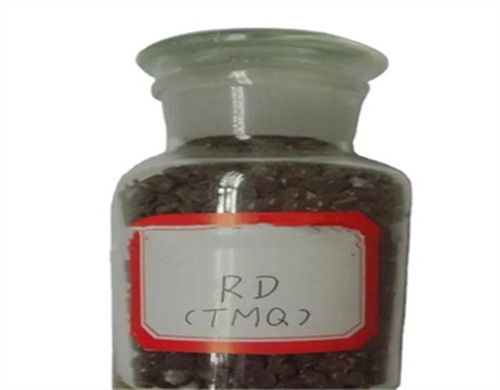

- Purity:95%

- Type:Rubber antioxidant

- Appearance:Amber to Brown Flake or Granular

- Melting point:45-46°C

- Application:For nitrilebutylbenzene

- Production Capacity:10000 Kilogram/Kilograms per Day

- Package:As the client's request

rubber antioxidant tmq for sale products,antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

the commonly used rubber antioxidant can be divided into primary antioxidant and secondary antioxidant according to the anti-aging mechanism [13]. the primary antioxidants, such as aryl amines and phenolic antioxidants, could inhibit the propagation reaction by supplying the reactive hydrogen atom to the free radicals.

rubber antioxidants and their transformation products

amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

Factory Hot Sale Rubber antioxidant In Stock,in this study, we chose natural rubber (nr) as a matrix and provided a screening strategy based on diverse natural phenolic antioxidants to evaluate their ability in protecting nr composites. thymol, α-tocopherol, and lipid-soluble epigallocatechin gallate (lsegcg) were chosen from 18 natural phenolic antioxidants as potential alternative

analysis of rubber antioxidant tmq (rd) in different rubber

this paper discusses the application of rubber antioxidant tmq (rd) in various rubber products such as all-steel and semi-steel radial tires, hoses and belts, and its advantages, demonstrating its excellent anti-aging ability.

Factory Hot Sale Rubber antioxidant In Stock,the complexity of thermo-oxidative aging factors along with the lack of quantitative tools significantly hampers its applications. so, building a screening strategy to quickly and easily find an appropriate and eco-friendly ao is imperative. in this study, we chose natural rubber (nr) as a matrix and provided

recent progress in the rubber antioxidants Rubber Auxiliary Agent

the anti-aging behavior of styrene-butadiene rubber (sbr)/silica with cos-gmmp, as well as the low molecule antioxidant gm, was systematically investigated by the accelerated thermal aging...

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

effect of antioxidants on aging of the chloroprene rubber

n‐(1,3‐dimethylbutyl)‐n′‐phenyl‐p‐phenylenediamine (6ppd), an anti‐ageing agent in rubber antioxidant tmq used in milk lines, may migrate into the milk and cause safety issues.

rubber antioxidants and chemical 6ppd,amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

- Does antioxidant 2246 protect rubber from aging?

- Among them, antioxidant 2246 has a good performance to protect rubber from aging caused by heat, oxygen, and metals. Because hydrogen in phenolic antioxidants can combine with the oxygen in air, their antiaging efficiency is therefore lowered compared with amine antioxidants [21, 22].

- Which rubber antioxidants are used in China?

- Amine antioxidants are the main rubber antioxidants produced and used in China, of which 6PPD and 2,2,4-Trimethyl-1,2-dihydroquinoline (TMQ, RD) have the highest production, accounting for more than 80% of the total amine antioxidants.

- What are the TPS of rubber antioxidants?

- The TPs of rubber antioxidants have been observed in some studies under environmental conditions. As one of the widespread rubber antioxidants, amine antioxidants (PPDs: TMPPD, DPPD, 6PPD, and 6PPDTZ) could react with O 3 (in parts per billion volume levels) in the environment and produce PPD-quinone .

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.