rubber antioxidants: tmq, 6ppd, ippd chemical products

- Classification:Chemical Auxiliary Agent

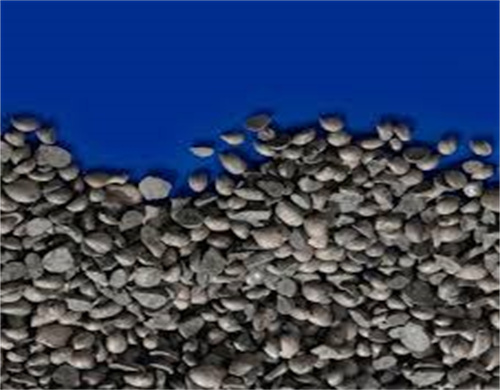

- Purity:98%

- Type:Anti-aging agent

- Appearance:Gray Purple or Purple Brown Granular

- Melting point:45-46°C

- Application:For nitrilebutylbenzene

- Production Capacity:50000000t/Year

- Package:25 kg plastic woven bag

advantages of rubber antioxidant ippd in tropical regions,explore the benefits of rubber antioxidant ippd in enhancing the durability and market competitiveness of rubber products in tropical climates. learn how ippd can extend the service life of rubber and improve product resistance to aging.

rubber antioxidant IPPD, or n-isopropyl-n'-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. It prevents degradation caused by heat, oxygen, and flex cracking.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

the rubber antioxidant market is expected to expand significantly in the future due to the increasing demand for antioxidants in the manufacture of various rubber products used in the tire industry, automotive industry, and others.

rubber antioxidants crossland chemicals,it can be applied to tires, conveyor belts, rubber pipes, cables, etc., and rubber products that need dynamic and static oxidation and ozone resistance protection. 6ppd has a stabhization effect on many solution and emulsion polymers.

comparative analysis of rubber antioxidant ippd and other

this article analyzes the rubber antioxidant ippd and other antioxidants in detail in terms of anti-aging performance, application areas and cost-effectiveness to help rubber industry customers make wise decisions when choosing antioxidants.

rubber antioxidants and chemical 6ppd,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

enhancing rubber performance with antioxidant ippd

discover how the antioxidant ippd enhances the performance of rubber products. learn about its unique properties, applications in various industries, and the growing demand for high-performance antioxidants.

transformation products of tire rubber antioxidant 6ppd for sale,6ppd reactions with ozone generate numerous ubiquitous and potentially bioactive transformation products that can be detected in tire rubber particles and roadway environments.

rubber antioxidant ippd 4010na cas:101-72-4 with cheap price

get high-quality rubber antioxidant ippd 4010na at a pocket-friendly price. ideal for rubber tire manufacturing, this product is the perfect choice for purchasers.

rubber antioxidants and their transformation products,phosphite antioxidants mainly include tris (nonylphenyl) phosphate (tnp), tris (1,2,2,6,6-pentamethylpiperidinyl) phosphite (gw-540), and tris (2,4-di-tert-butylphenyl) phosphite (irgafos168). gw-540 is widely used in tires blended with styrene butadiene rubber and polybutadiene rubber.

- Are there any new motor vehicle tires that don't contain 6PPD?

- USTMA is not aware of any new motor vehicle tires available today that do not contain 6PPD. 6PPD-quinone, or 6PPDQ, is a recently discovered transformation product of 6PPD that may form when 6PPD reacts with oxygen or ozone under certain conditions. 6PPDQ is not used in U.S. tire manufacturing.

- Is pyrolysis a standalone solution for 6PPD decontamination and EOL tire upcycling?

- This indicates that pyrolysis is not a standalone solution for 6PPD decontamination and EOL tire upcycling, and solvent extraction is essential for isolating this chemical. 6PPD can be catalytically converted to value-added products, such as cyclohexylamine, using a conventional Pd/C catalyst under hydrogen pressure.

- Can pyrolysis irradiation decontaminate crumb rubber?

- Volumetric heating of the carbon-black-based particles indicates uniform heating during microwave irradiation. The direct pyrolysis of crumb rubber, however, is not an effective decontamination strategy as 6PPD emerges in the pyrolysis oil product. We then turn to microwave-assisted solvent extraction to isolate 6PPD from the feedstock.