4010na rubber antioxidant: enhancing durability

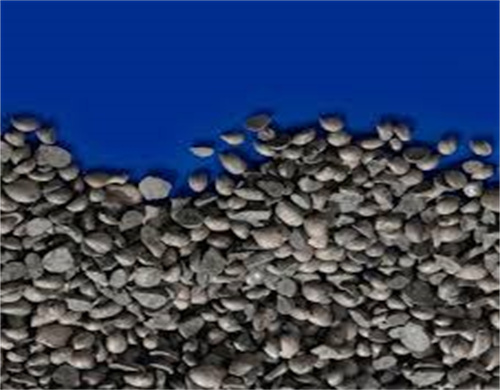

- Classification:Chemical Auxiliary Agent

- Purity:97%

- Type:Rubber additive antioxidant

- Appearance:Grey to Very Dark Grey Solid

- Content:95%

- Application:Shoe Soles, auto tyre

- Production Capacity:5000 Ton/Tons per Month

- Package:25kg/barrel

synergistic effects of antioxidant and silica on enhancing,in this work, the thermo-oxidative aging performance of antioxidant n-isopropyl- n ′-phenyl- p -phenylenediamine (4010na)/silica (sio 2)/natural rubber (nr) composite was evaluated by the variations of mechanical properties and chemical structure after aging at 100 ℃.

4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential cons

antioxidant 4010na-zhejiang huangyan zhedong rubber auxiliary

zero point three zero. [performance] natural rubber, synthetic rubber and latex with excellent general antioxidant, excellent protective properties of ozone cracking; also the heat, oxygen, light and aging two protective agent.

effectiveness of different kinds of antioxidants in resin,the results show that the physicomechanical properties of the biir vulcanizate severely deteriorate when antioxidant 4010na is used. among the other antioxidants used, the phenolic-type antioxidant bht is found to be better for the resin-cured biir vulcanizate of this study. 1 introduction.

the aging properties and phase morphology of silica filled

large amounts of antioxidants are used in unsaturated rubber composites, such as butadiene rubber (br), which would inevitably cause surface discoloration. in this study, silicone rubber (vmq) was blended with br for improving its anti-aging properties.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

source rubber antioxidant ippd(4010na) high quality rubber

rubber antioxidant 4010na (ippd) 4010na is a comprehensive and efficient rubber antioxidant, it has good protection against ozone aging, metal aging and resistance to flexing, fatigue and cracking; suitable for the rubber products working under static, dynamic or intermittent conditions; low melting point and easy to disperse, the solubility in

rubber antioxidant 4010na(ippd) price,rubber antioxidant 4010na (ippd) a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature, fatigue and flex resistance to rubber compounds.

performance characteristics of rubber additives and its

the main varieties of alkylaryl p-phenylenediamine antioxidants are antioxidants 4010, 4010na, 4020 and h. anti-aging agent 4020 is currently the largest amount of antioxidants used in tire rubber compounds. it has excellent protection against ozone aging and flex crack aging.

highly aging-resistant elastomers doped with antioxidant,a novel aging-resistant styrene-butadiene rubber (sbr) composite is prepared using the antioxidant n-isopropyl-n'-phenyl-p-phenylenediamine (4010na) loaded inside of halloysite clay nanotubes and used as filler.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- What causes oxidative aging of rubber?

- Various external factors, including oxidative agents (such as oxygen), heavy metals, UV rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. This review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- How does rubber antioxidant work?

- To prolong the service life of rubber composites by retarding their aging processes, rubber antioxidant initially relies on the use of a coating, such as paraffin, and coal tar, to physically isolate oxygen, but this protective layer would quickly lose the utility due to wear.