Rubber Antioxidant 6PPD technical data sheet

- Classification:Chemical Auxiliary Agent

- Purity:98.9%

- Type:Rubber additive antioxidant

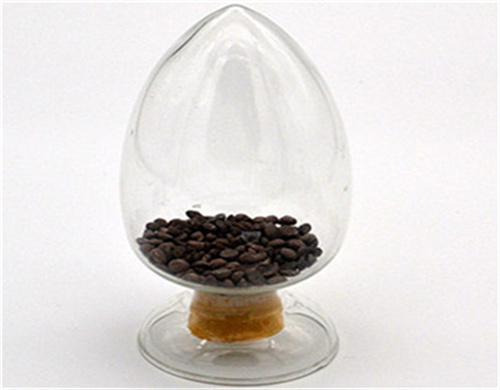

- Appearance:Dark brown to dark violet pastilles

- Feature:Chemical Resistance

- Application:Natural Rubber, Synthetic Rubber Common Use

- Storage:Store in a Cool, Dry Place

- Package:Ply Kraft Paper Bag

rubber antioxidant 6ppd 4020 793-24-8 manufacturer,rubber antioxidant 6ppd is a high-performance antioxidant that is designed to protect rubber products from oxidative degradation caused by environmental factors such as heat, oxygen, and ozone. it is a dark purple-brown solid that is soluble in organic solvents and has a melting point of approximately 46-50℃.

application: 6ppd is used for rubber products with high efficiency, low poison and low solvent extraction amount. also used as stabilizer in synthetic rubber which is widely applied in many kinds of rubber products. package: net weight: 25kg/bag, packed in paper bag lined with plastic bag. storage: it should be stored at room temperature.

rubber antioxidants: tmq, 6ppd, ippd chemical products

Rubber antioxidant 6ppd, n-1,3-dimethylbutyl-n'-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. It prevents degradation caused by heat, oxygen and flex cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and extending service life

rubber aging agent 6ppd(4020) national standard quality,Detailed introduction. Rubber antioxidant 4020/6PPD. Chemical name: N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine. Molecular formula: C18H24N2. CAS number: 793-24-8. Molecular weight: 268.40. 6PPD is a phenylenediamine rubber antioxidant with good compatibility with rubber, not easy to bloom, low volatility and low toxicity.

rubber antioxidant 6ppd (4020) a must-have for improving

rubber antioxidant 6ppd (4020) is a highly efficient multi-purpose antioxidant with excellent antioxidant and high temperature resistance properties. it can significantly improve the durability and protective effect of rubber products, and is especially suitable for complex and harsh dynamic working conditions. .

6ppd rubber antioxidant: characteristics, applications,6ppd (n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a highly effective rubber antioxidant with notable characteristics, including excellent heat resistance, anti-flex cracking properties, and compatibility with various rubber types.

antioxidant 4020 (6ppd) rubber antioxidante

it has powerful antiozonant and antioxidant properties with excellent high temperature , fatigue and flex resistance to rubber polymers. and enhance polymer resistance ability. will discolor compounds and cause severe contact and migration staining.

rubber antioxidants and their transformation products,as one of the widespread rubber antioxidants, amine antioxidants (ppds: tmppd, dppd, 6ppd, and 6ppdtz) could react with o 3 (in parts per billion volume levels) in the environment and produce ppd-quinone .

overview of rubber antioxidant 6ppd (4020) 20mt price

this article discusses the application prospects of rubber antioxidant 6ppd (4020) in mechanical products, analyzes its anti-aging properties and advantages in improving product durability, and provides practical reference for industry practitioners.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,the authors claimed that the thermal aging resistance rubber compounds containing nr-g-ppdam were better than those containing low molecular weight antioxidant 6ppd.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.