antioxidants vulkanox 4020 6ppd rubber antioxidant, grade

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber chemicals

- Appearance:Gray Purple or Purple Brown

- Grade:Industrial Grade

- Application:tyres, rubber, plastic, adhesive tape, wires

- Production Capacity:3000 Ton/Year

- Package:25kg/drum

factory price rubber antioxidant 4020 liqiud lanxess,shelf life and packaging specialty application and performance fluids.antioxidant 4020. n-(1.3-dimethylbutyl)-n'-phenyl-p-phenylendiamine.vulkanox 4020 lg

multi chemicals offering antioxidants vulkanox 4020 6ppd rubber antioxidant, grade standard: industrial grade, packaging size: 25kg at rs 440/bag in jalandhar, punjab. also find rubber antioxidants price list id: 25847320873

deepl翻訳:高精度な翻訳ツール deepl translate

テキストや文書ファイルを瞬時に翻訳します。個人でもチームでも、高精度の翻訳をご活用いただけます。毎日、何百万もの人々がdeeplを使って翻訳しています。

rubber aging agent 6ppd(4020) with high quality,rubber aging agent 6ppd(4020) with high quality rubber additives high efficiency anti aging. rubber antioxidant 4020/6ppd. chemical name:n-(1,3-dimethyl-buty)-n’-phenyl-p-phenylenediamine molecular: c18h24n2 cas no.: 793-24-8. molecular weight: 268.40. hs code: 3812301000

rubber antioxidant 6ppd 4020 for hot sale

detail introduction. product name: ippd (4010 na) chemical name: n-isopropyl-n'-phenyl-p-phenylenediamine. cas no.: 793-24-8. product specification: -6ppd is an outstanding antioxidant and antiozonant, generally used for natural rubber and synthetic rubber. -6ppd can slow rubber’s fatigue degradation under static and dynamic operating conditions.

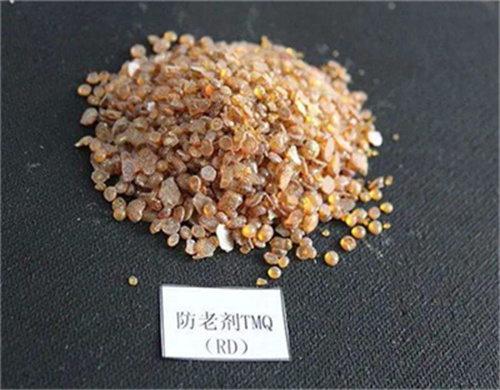

antioxidant 4020 hydachem.com,antioxidant 4020 dark brown to dark violet pastilles relative density of 0.986-1.00. soluble benzene, acetone, ethyl acetate, toluene dichloromethane and slightly soluble in ether, do not dissolve in water.

antioxidant pa100 power chemical

pa100 particularly mixed with same amount 4020 or 4010 na is the most antiozonant style to extend the useful life of tire. the reason is that the two kinds antioxidants have synergism. antioxidant 4020 and 4010 na provides the short-time protection at the beginning, while pa100 provides long-term ozone, oxygen and heat protection making it

rubber antioxidants and their transformation products,antioxidants are widely used to improve the performance of rubber, and their production, especially 6ppd, is annually maintained at a high level . amine antioxidants and tps have been generally detected in the environment, especially in water, air, and dust, indicating that they can be transported through the atmosphere and rivers.

antioxidant 4020 (6ppd) chemical supplier

cas number 793-24-8. antioxidant 4020 (6ppd) product name: 6ppd product form: granular or flake chemical name: n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

- What are active antioxidant packaging systems?

- Active compounds can be incorporated into packaging films in many forms. Then antioxidants migrate and diffuse in the packaging material and subsequently release into the food, thereby reducing oxidation by preventing the formation or spread of free radicals. Fig. 1. Main active antioxidant packaging systems.

- How to choose the right antioxidants in packaging?

- The proper choice of antioxidants in packaging depends on their molecular size, polarity and release properties (Nerin, Silva, Manso, & Becerril, 2016). Active substances have to diffuse through the polymer macromolecules.

- What is the release mechanism of antioxidants in active packaging?

- The release mechanism of antioxidants in active packaging, the factors affecting the controlled-release and the packaging design considerations are introduced from the aspects of packaging material components (polymer matrix and active substances), combination of other components and preparation methods.

- What is the second stage of active antioxidant packaging?

- The second stage is speed controlled release, where the active substance has been released but the release rate is changed from the initial one. Active antioxidant packaging requires a sustained-release system where a requisite concentration range of antioxidants are maintained for a long time to ensure effectiveness.