rubber antioxidant 4020(6ppd) prospector by ul

- Classification:Chemical Auxiliary Agent

- Purity:99%

- Type:Rubber antioxidant

- Appearance:Dark gray to black solid

- Flash point:204°C

- Application:Rubber goods/plastic/shoes/tyre

- Storage:Cool Dry Place

- Package:25 kg/bag,1000 kg/bag,customized packaging

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

access 3 properties in additives. create your free account or sign into prospector. processing find specific processing information for rubber antioxidant as well as general information for the additive -- antioxidant / heat stabilizer generic family. register or sign in for more information.

performance characteristics of rubber additives and its application price

antioxidant 3100 has one or two compatibilizing genes introduced into the benzene ring on both sides of the molecular structure, so its solubility in rubber increases, the amount in rubber can be increased, and the application of antioxidants 4010na and the defect

screening p-phenylenediamine antioxidants, their transformation,recently, roadway releases of n,n′-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers.

recent progress in the rubber antioxidants price

in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rubber antioxidant 6ppd(4020) (high-class) henan rtenza supplier,find products that are predicted to be compatible with rubber antioxidant 6ppd(4020) (high-class). this list of compatible products is generated out of estimated hsp values. a practical determination of these hsp values would provide higher certainty. learn more.

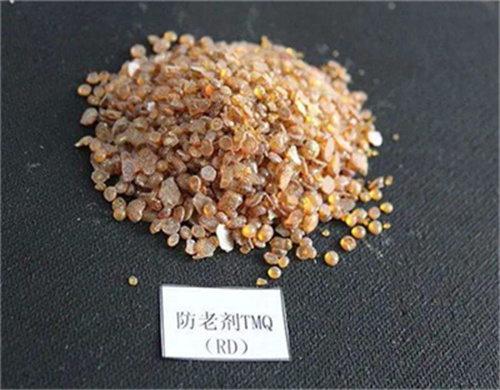

rubber antioxidant 6ppd ippd tmq rubber accelerator rubber

antioxidant 4020 (6ppd) is a versatile product that offers several benefits to manufacturers of rubber products.a type of ursol rubber antioxidant, 6ppd has good compatibility with rubbers, seldom blooming, low volatility, low toxicity, with great.

environmental chemical rubber antioxidants,2.1. amine antioxidants amine antioxidant is the most common rubber antioxidant, which was produced as early as the 1970s and widely used in the rubber industry. typical amine antioxidants include diaryl-secondary amine, acetone-amine condensation product, p-phenylenediamine, and aldehyde-amine condensation product antioxidants [].

rubber antioxidant 6ppd 4020 with good price

rubber antioxidant 6ppd 4020 product name:ippd (4010 na)chemical name:n-isopropyl-n'-phenyl-p-phenylenediaminecas no.:793-24-8product specification:rubber antioxidant -phenyl-p-phenylenediamine4020 6ppdname:4020 6ppdcas no.793-24-8einecs

recent progress in the rubber antioxidants price,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Which industrial rubber additives have higher chemical concentrations?

- Furthermore, we quantified 15 other industrial rubber additives (including bonding agents, vulcanization accelerators, benzotriazole and benzothiazole derivatives, and diphenylamine antioxidants), observing that PPD-derived chemical concentrations were 0.5–6 times higher than these often-studied additives.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.