6ppd rubber antioxidant: characteristics, applications, combinations

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber antioxidant

- Appearance:Light brown or white powder or granule

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Production Capacity:5000 Ton/Tons per Year

- Package:Package in 25kgs bag

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

6ppd (6ppd or n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a widely used rubber antioxidant that plays a vital role in the production of rubber products. this article aims to provide an overview of 6ppd, its characteristics, its applications in rubber product manufacturing, potential product combinations, and important considerations for commercial procurement. 1. what is 6ppd? 6ppd.

rubber antioxidant 6ppd for tyre, belt

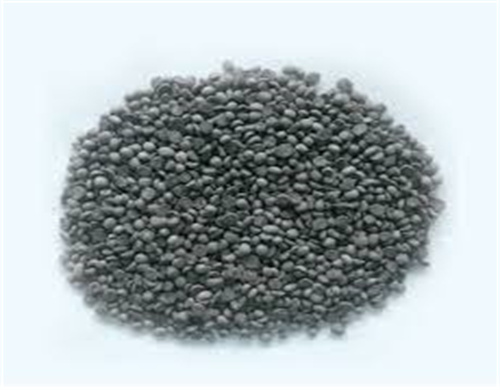

product name: rubber antioxidant 6ppd cas no.: 793-24-8 mf: c18h24n2 einecs no.: 212-344-0 appearance: dark purple granular.experience our prompt service, reliable delivery, and personalized support, ensuring your needs are met with utmost.

end-of-life tire decontamination from 6ppd and upcycling,abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

sunlight-induced transformation of tire rubber antioxidant n-(1,3

the huge consumption of the tire rubber antioxidant n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd) has resulted in pervasive contamination in aquatic environments. more importantly, the transformation product of 6ppd, i.e., 6ppd-quinone (6ppd-q), is raising increasing concerns due to its high toxicity to aquatic organisms. however, whether and how 6ppd-q can be formed from 6ppd in.

rubber antioxidants: tmq, 6ppd, ippd chemical products,6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and extending the service life of rubber products.

Rubber Antioxidant 6PPD 4020 from China supplier

6ppd, or 6-phenyl-1,3-dihydro-2h-benzotriazole, is an antioxidant and antiozonant of substantial importance in the rubber industry. it safeguards rubber compounds and tire treads from degradation caused by ozone and quinone transformation products.

transformation products of tire rubber antioxidant 6ppd in,ples.28−32 6ppd is ubiquitously used in tire rubbers as an antioxidant at 0.4−2% by weight,33 where it is designed to quickly react with ground-level o 3 to protect rubber elastomers.34,35 such reactions inevitably form other trans-formation products (tps 21,34

environmental rubber antioxidant 6ppd and toxicological

n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd) serves as an antioxidant utilized as an additive in rubber tires to impede oxidation (cao et al., 2022, jin et al., 2023a).the escalated utilization of antioxidants in rubber and tire-associated products has.

a ubiquitous tire rubber–derived chemical induces acute science,in u.s. pacific northwest coho salmon (oncorhynchus kisutch), stormwater exposure annually causes unexplained acute mortality when adult salmon migrate to urban creeks to reproduce. by investigating this phenomenon, we identified a highly toxic quinone transformation product of n (1,3-dimethylbutyl)- n ′-phenyl-p-phenylenediamine (6ppd), a.

- Are there alternatives to 6PPD as a rubber antioxidant?

- Nevertheless, conclusive studies identifying superior alternatives to 6PPD as a rubber antioxidant remain scarce in the current literature. Urbanization has resulted in an increase in surface runoff, a phenomenon that plays a pivotal role in the transportation of chemicals originating from tire wear into aquatic environments.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.