rubber antioxidant tmq(rd) (high-class) technical datasheet supplier

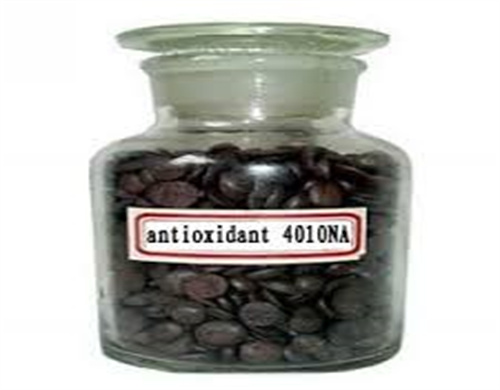

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Rubber antioxidant

- Appearance:Amber to Brown Flake or Granular

- MOQ:500kg

- Application:Coating Auxiliary Agents

- Production Capacity:10000 Kilogram/Kilograms per Day

- Package:As the client's request

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rubber antioxidant tmq(rd) (high-class) is suitable for tires, rubber tubes, gummed tapes, rubber overshoes and general industrial rubber products. read more view less download product type antioxidants chemical composition 2,2,4-trimethy1-1,2 26780-96.

growth of ceco-mof in dendritic mesoporous organosilica as highly

doi: 10.1016/j.cclet.2024.109669 corpus id: 267950246 growth of ceco-mof in dendritic mesoporous organosilica as highly efficient antioxidant for enhanced thermal stability of silicone rubber @article{zhu2024growthoc, title={growth of ceco-mof in dendritic.

recent progress in the rubber antioxidants price,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and.

rubber antioxidants and their transformation products mdpi

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

tmq antioxidant for rubber industry: enhancing performance and,in the realm of rubber manufacturing, the utilization of effective rubber additives is crucial to ensure superior product quality and longevity. one such essential rubber additive is the antioxidant tmq, also known as rd. in this article, we will delve into what tmq is, its role in rubber product production, and the advantages it holds over other similar products in the market. tmq antioxidant.

antioxidant modified graphene oxide for robust and highly aging

in this work, rubber antioxidant poly(1,2-dihydro-2,2,4-trimethylquinoline) (rd) was introduced as organic surface modifier of graphene oxide (go) for the preparation of robust and highly anti-aging rubber composites. it was found that rd was chemically grafted on.

analysis of rubber antioxidant tmq (rd) in different rubber products,this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

Rubber Chemical Product Antioxidant Tmq/Rd

This product is a pollution antioxidant and a high-performance general antioxidant among amine stabilizers. It has excellent antioxidant, ozone resistance, flex crack resistance, and sunlight crack resistance. It has a strong inhibitory effect on toxic metals such as copper or manganese and is suitable for all types of synthetic rubber and natural rubber.

environmental chemical rubber antioxidants,2.1. amine antioxidants amine antioxidant is the most common rubber antioxidant, which was produced as early as the 1970s and widely used in the rubber industry. typical amine antioxidants include diaryl-secondary amine, acetone-amine condensation product, p-phenylenediamine, and aldehyde-amine condensation product antioxidants [].

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- How many rubber antioxidants are produced in China?

- China is one of the main countries producing rubber antioxidants, and the production accounts for more than 70% of the total amount globally. The production of rubber antioxidants in China ranged from 365,000 to 378,000 tons during 2016–2020, showing a constant annual trend .