6ppd rubber antioxidant: characteristics, applications, combinations

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber antioxidant

- Appearance:Light brown or white powder or granule

- Flash point:204°C

- Application:Rubber goods/plastic/shoes/tyre

- Production Capacity:1000 Metric Tons per Month

- Package:20kg kraft bags,500kgs/pallet

end-of-life tire decontamination from 6ppd and upcycling,abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

6ppd (6ppd or n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a widely used rubber antioxidant that plays a vital role in the production of rubber products. this article aims to provide an overview of 6ppd, its characteristics, its applications in rubber product manufacturing, potential product combinations, and important considerations for commercial procurement. 1. what is 6ppd? 6ppd.

rubber antioxidant 6ppd for tyre, belt

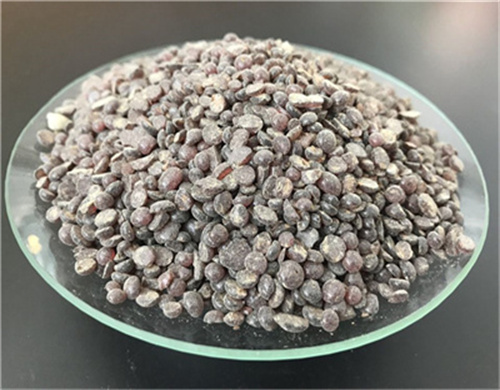

product name: rubber antioxidant 6ppd cas no.: 793-24-8 mf: c18h24n2 einecs no.: 212-344-0 appearance: dark purple granular.provide high quality products with customer satisfaction at the core. share this product inquiry now description n-(1,3 c.

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

environmental fate of tire-rubber related pollutants 6ppd and 6ppd-q: a

abstract. to enhance tire durability, the antioxidant n- (1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd) is used in rubber, but it converts into the toxic 6ppd quinone (6ppd-q) when exposed to oxidants like ozone (o 3), causing ecological concerns. this review synthesizes the existing data to assess the transformation, bioavailability.

rubber antioxidants: tmq, 6ppd, ippd chemical products,6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and extending the service life of rubber products.

antioxidant 6ppd / 4020 with factory price and good quality

6ppd is an organic chemical widely used as stabilising additive (or antidegradant) in rubbers, such as nr, sbr and br; all of which are common in vehicle tires. [1] although it is an effective antioxidant it is primarily used because of its excellent antiozonant performance. performance.

p-phenylenediamines and p-phenylenediamine quinone derivatives in,in china, ppds are widely used as commercial rubber antioxidants, with annual production of 200,000 tons (seiwert et al., 2022). the widespread use of these chemicals explains their high dfs. oxidation products of ppds other than 6ppd-q, such as ippd

comprehensive overview of 6ppd rubber antioxidant types in 2024

n-(1,3-dimethylbutyl)-n’-phenyl-p-phenylenediamine (6ppd) and its derivative, 6ppd-quinone, have significant applications in the rubber industry due to their antioxidant properties. however, concerns and data gaps persist regarding their environmental impact and overall safety.

a ubiquitous tire rubber–derived chemical induces acute science,in u.s. pacific northwest coho salmon (oncorhynchus kisutch), stormwater exposure annually causes unexplained acute mortality when adult salmon migrate to urban creeks to reproduce. by investigating this phenomenon, we identified a highly toxic quinone transformation product of n (1,3-dimethylbutyl)- n ′-phenyl-p-phenylenediamine (6ppd), a.

- What causes 6ppd-q in soil and tire rubber wear particles (TRWPS)?

- There is a linkage between 6PPD-Q in soil and tire rubber wear particles (TRWPs), indicating its origin from sources associated with vehicular activities (Klockner et al., 2019). Approximately 50% of TRWPs can infiltrate the soil, releasing bound chemicals like 6PPD (Klockner et al., 2019).

- Is 6PPD recalcitrant under harsh pyrolysis?

- This demonstrates the recalcitrant nature of 6PPD under harsh pyrolysis conditions and suggests solvent extraction is necessary for its removal. The TGA curve (Supplementary Fig. 11) of 6PPD shows a maximum degradation at ~300 °C and suggests that some 6PPD in the tires may sublime into the liquid product before the rubber degrades.

- What are the effects of 6PPD & 6ppd-q in air and dust?

- Evaluating different Impacts of 6PPD and 6PPD-Q in air and dust. The presence of 6PPD and 6PPD-Q contributes to inhalation hazards by releasing particulate matter and volatile organic compounds into the air. Inhalation of these pollutants poses risks to respiratory health and may lead to various respiratory issues upon exposure.

- Why is 6ppd-q present in soil?

- The presence of 6PPD-Q in soil predominantly arises from the deposition of atmospheric particles or dust that carry 6PPD-Q. Soil samples collected from Hongkong's New Territories and Kowloon roadside showed varied concentrations of 6PPD-Q like 9.50–936 ng/g (Cao et al., 2022).