contitech breaks ground on hydraulic hose plant in mexico

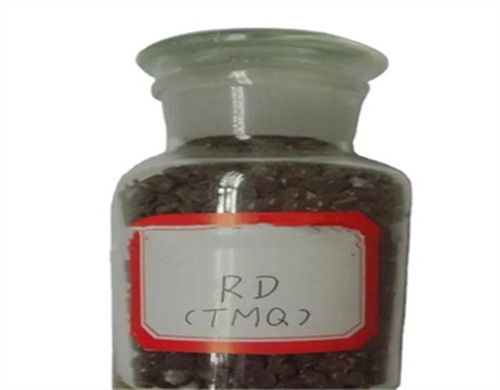

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Rubber additive antioxidant

- Appearance:Gray Purple or Purple Brown Granular

- Brand Name:Gobiotech

- Application:Petroleum Additives

- Production Capacity:3000 Ton/Year

- Package:25kg/drum

continental $90m investment in mexico fuels new hydraulic,our education in automotive component advancements continues with radiator hoses and serpentine belts, highlighting the use of durable epdm rubber that reduces the number of replacements.

from when contitech first announced plans for a new hydraulic hose manufacturing facility in 2022 to when it broke ground jan. 26, a lot has changed. conti's andreas gerstenberger and jim hill spoke exclusively with rubber news about the project.

around $90 million investment in mexico for continental's new

the german technology company continental has announced, together with the governor of aguascalientes, the construction of its new hydraulic hose plant for industrial purposes. the planned investment is of around 90 million dollars and is one of the biggest investments for continental’s group sector contitech in 2024.

contitech to build €82m hydraulic hose plant in mexico,new facility in the west-central state of aguascalientes set for operation in 2025. hanover, germany contitech ag, part of the german technology group continental ag, is investing $90 million (€82 million) to establish an hydraulic hose production facility in mexico.

analysis of rubber antioxidant tmq (rd) in different rubber

this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

continental plans to invest over $40 million- rubber world,a new, state-of-the-art hydraulic hose production facility will be built in san luis potosi, mexico, to increase and complement manufacturing capabilities in the region and beyond. the planned investment is worth more than $40 million.

continental to build $40m hydraulic hose production facility

fairlawn, ohio continental ag has announced plans to invest over $40 million (€38.3 million) to build a new industrial hydraulic hose production facility in san luis potosi, mexico.

continental invests in us$90 mn hose plant in mexico,the new facility will be continental’s 22nd plant in mexico and the second in the state of aguascalientes. continental’s operations in the country produce and develop automotive components, rubber products and tyres and are exported to different countries, occupying more than 23,000 employees.

rubber antioxidants and chemical 6ppd

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental

continental breaks ground on hydraulic hose factory in mexico,aguascalientes, mexico—contitech's hydraulic hose factory in mexico is taking shape. the business group of continental a.g. broke ground on the project and celebrated its start with a january ceremony. the plant, first announced in 2022, should begin production in the second half of 2025.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- How does rubber antioxidant work?

- To prolong the service life of rubber composites by retarding their aging processes, rubber antioxidant initially relies on the use of a coating, such as paraffin, and coal tar, to physically isolate oxygen, but this protective layer would quickly lose the utility due to wear.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.