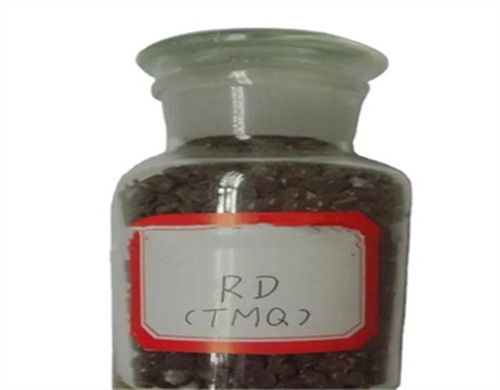

rubber antioxidants tmq Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Antioxidant

- Appearance:Grayish purple to purple brown granular

- Grade:Superior Class

- Application:used in manufacture of tires

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

recent progress in the rubber antioxidants Rubber Auxiliary Agent,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants.

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

synthesis and properties of a novel reactive and low

the addition of antioxidants to rubber is one of the most economical and effective methods for delaying rubber aging. however, antioxidant migration can cause environmental pollution. to address this issue, a new reactive antioxidant was synthesized via the chemical bonding of glycidyl methacrylate (gma) and p-aminodiphenylamine (ppda). the

(pdf) rubber antioxidants and their transformation products,in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing...

effectiveness of different kinds of antioxidants in resin

the results show that the physicomechanical properties of the biir vulcanizate severely deteriorate when antioxidant 4010na is used. among the other antioxidants used, the phenolic-type antioxidant bht is found to be better for the resin-cured biir vulcanizate of this study. keywords.

relationship between the aging thermal oxygen and mechanical,a novel functional carbon nanofiller cnts-cooh-rd with antioxidant aging properties was prepared by grafting the antioxidant rd onto the surface of carboxylated carbon nanotubes. filler cnts-cooh-rd greatly improves the heat and oxygen aging resistance and tribological properties of nbr composites.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

while extensive efforts have been directed toward the research of rubber antioxidants, there are still several scientific and technological issues that remain unsolved, and the perspectives on...

rubber antioxidants and chemical 6ppd,in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

study on antioxidant rd by gc/ms semantic scholar

the antioxidant rd, widely used for rubber, has been determined and analyzed by gc-tof-ms and tof-ms using ei (electron ionization) source. it is found from tic of gc-eims that the amount of dipolymer in rd is the largest with best thermal stability.

rubber antioxidants and their transformation products,amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.