transformation products of tire rubber antioxidant 6ppd for sale

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Anti-aging agent

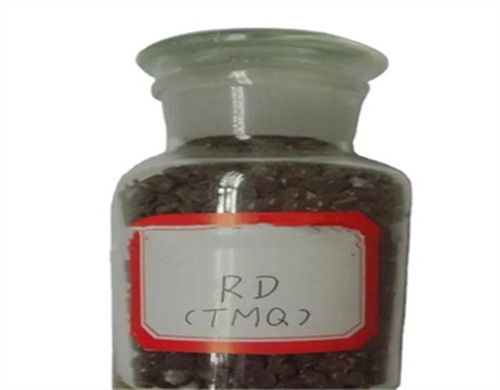

- Appearance:Dark brown to dark vilet pastilles or flake

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Production Capacity:100 Metric Ton/Metric Tons per Month

- Package:25kg plastic woven bag

eco-friendliness rubber antioxidant tmq for tire,antioxidants which are indispensable functional additives used in rubber tires, are released into aquatic habitats from tire wear particles (twp), collected in water bodies, and threaten the aquatic ecosystem.

6ppd reactions with ozone generate numerous ubiquitous and potentially bioactive transformation products that can be detected in tire rubber particles and roadway environments.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

the rubber antioxidant market is expected to expand significantly in the future due to the increasing demand for antioxidants in the manufacture of various rubber products used in the tire industry, automotive industry, and others.

big discount rubber antioxidant 6ppd for tyre,automobile tires require functional rubber additives including curing agents and antioxidants, which are potentially environmentally available from tire and road wear particles (trwp) deposited in soil and sediment.

analysis of rubber antioxidant tmq (rd) in different rubber

this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

rubber antioxidant tmq (rd) 26780-96-1 manufacturer,with its exceptional oxidation resistance, rubber antioxidant tmq is ideal for prolonging the lifespan of rubber products such as tires, rubber tubes, and cables. it protects against cracking, breaking, and becoming brittle, even in high-temperature and high-humidity conditions.

analysis on the application of rubber antioxidant tmq (rd) for sale

this paper discusses the application of rubber antioxidant tmq (rd) in various rubber products such as all-steel and semi-steel radial tires, hoses and belts, and its advantages, demonstrating its excellent anti-aging ability.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

a novel filling antioxidant (lig-g-rt) to improve the mechanical properties and antiaging performance of styrene-butadiene rubber (sbr) composites was prepared by grafting antioxidant...

rubber antioxidants and chemical 6ppd,gw-540 is widely used in tires blended with styrene butadiene rubber and polybutadiene rubber. tnp is suitable for nr, sr, latex, and plastic products. as a stabilizer and antioxidant, it could endow rubber products with considerable heat resistance [29].

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].

- Which rubber antioxidants are used in China?

- Amine antioxidants are the main rubber antioxidants produced and used in China, of which 6PPD and 2,2,4-Trimethyl-1,2-dihydroquinoline (TMQ, RD) have the highest production, accounting for more than 80% of the total amine antioxidants.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.