transformation products of tire rubber antioxidant 6ppd for sale

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Rubber antioxidant

- Appearance:Amber to Brown Flake or Granular

- Ash Content:0.20%

- Application:tyres, motorcycles births

- Production Capacity: 500 Metric Tons per Month

- Package:25kg in kraft paper bag with PE bag inside

Rubber Antiageing Antiage Antioxidant 4020/6PPD price,this study revealed that sunlight-induced transformation of 6ppd could be an important origin of 6ppd-q in aquatic environments, providing significant insights to the potentially underestimated ecological risks of 6ppd.

6ppd reactions with ozone generate numerous ubiquitous and potentially bioactive transformation products that can be detected in tire rubber particles and roadway environments.

Best Price Rubber Antioxidant 6PPD CAS No.: 793-24-8

the tire antioxidant and antiozonant, 6ppd, is added to extend the polymer rubber lifetime. following environmental exposure, 6ppd transforms to its highly toxic quinone form n -...

6ppd rubber antioxidant: characteristics, applications,6ppd (n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a highly effective rubber antioxidant with notable characteristics, including excellent heat resistance, anti-flex cracking properties, and compatibility with various rubber types.

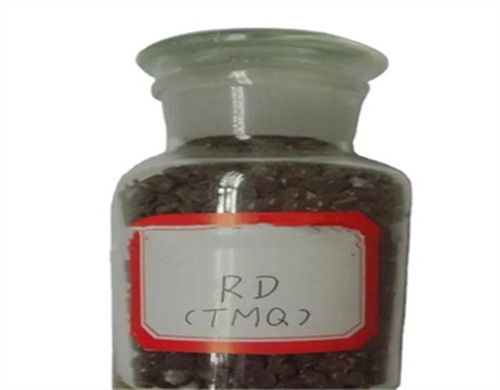

rubber antioxidants: tmq, 6ppd, ippd chemical products

Rubber antioxidant 6ppd, n-1,3-dimethylbutyl-n'-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. It prevents degradation caused by heat, oxygen and flex cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and extending service life

6ppd: its role in tire manufacturing and environmental impact,published oct 19, 2024. 6ppd, or n-(1,3-dimethylbutyl)-n’-phenyl-p-phenylenediamine, is a chemical compound widely used in tire manufacturing. its primary function as an antioxidant enhances tire durability by preventing degradation from environmental factors like heat, oxygen, and ozone. however, recent studies have raised concerns about

rubber anti-aging agent antioxidant 6PPD (4020) supplier

6ppd is an organic chemical widely used as stabilising additive (or antidegradant) in rubbers, such as nr, sbr and br; all of which are common in vehicle tires. although it is an effective antioxidant it is primarily used because of its excellent antiozonant performance.

environmental fate of tire-rubber related pollutants 6ppd,To improve tire durability, the antioxidant n-(1,3-dimethylbutyl)-n-phenyl-p-phenylenediamine (6PPD) is used in rubber, but when exposed to oxidants such as ozone (O3), it is converted into toxic 6PPD quinone (6PPD-Q), causing ecological problems.

a tire industry perspective on 6ppd replacement: the challenge

to act like 6ppd, a drop-in substitute must: function as antiozonant and antioxidant to help prevent the degradation and cracking of rubber compounds (unsaturated elastomers) by protecting against ozone attack, oxidation, and heat aging.

transformation products of tire rubber antioxidant 6ppd for sale,abstract: 6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppd), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation.

- Is 6PPD a toxic oxidant?

- To enhance tire durability, the antioxidant N- (1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine (6PPD) is used in rubber, but it converts into the toxic 6PPD quinone (6PPD-Q) when exposed to oxidants like ozone (O 3), causing ecological concerns.

- What solvent is used to remove 6PPD from EOL tires?

- Through batch extraction analysis and computational calculations, acetone is the best suited solvent for 6PPD removal from EOL tires of those tested. Furthermore, the batch extraction kinetics follow a first-order profile.

- Is 6PPD recalcitrant under harsh pyrolysis?

- This demonstrates the recalcitrant nature of 6PPD under harsh pyrolysis conditions and suggests solvent extraction is necessary for its removal. The TGA curve (Supplementary Fig. 11) of 6PPD shows a maximum degradation at ~300 °C and suggests that some 6PPD in the tires may sublime into the liquid product before the rubber degrades.

- What are the effects of 6PPD & 6ppd-q in air and dust?

- Evaluating different Impacts of 6PPD and 6PPD-Q in air and dust. The presence of 6PPD and 6PPD-Q contributes to inhalation hazards by releasing particulate matter and volatile organic compounds into the air. Inhalation of these pollutants poses risks to respiratory health and may lead to various respiratory issues upon exposure.