rubber antioxidant tmq for sale products

- Classification:Chemical Auxiliary Agent

- Purity:98.9%

- Type:Rubber chemicals

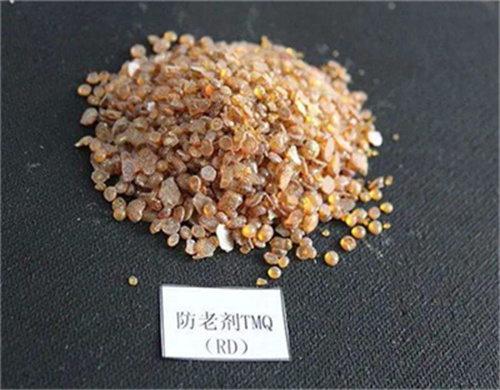

- Appearance:Dark brown to dark violet pastilles

- Shelf life:2 Years

- Application:Plastic Auxiliary Agents

- Production Capacity:10000 Kilogram/Kilograms per Day

- Package:As the client's request

safe protection against oxidation lanxess,sunlight and oxygen are vital for humans, but harmful to rubber, therefore lanxess offers an extensive range of antioxidants and antiozonants to prevent various types of aging in synthetic and natural rubber products.

antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

rubber antioxidants: tmq, 6ppd, ippd chemical products

tmq, also known as polymerized 2,2,4-trimethyl-1,2-dihydroquinoline, is a widely used rubber antioxidant. it provides excellent protection against heat, oxygen, and flex-cracking, enhancing the durability and performance of rubber products.

rubber antioxidant tmq, tq, tdq, rd for hot sale,mernox tq(tmq / tdq) is an inexpensive and highly potent staining type antioxidant most widely used in the rubber com-pounds based on nr, ir, sbr, br, nbr and other diene rubbers except cr (polychloroprene).

rubber antioxidants and their transformation products

amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

tmq antioxidant for rubber industry: enhancing performance,tmq, the antioxidant rd, is a vital additive in the rubber industry, safeguarding rubber products from premature aging and degradation. with its exceptional antioxidative properties, tmq enhances the durability, heat resistance, and flexibility retention of rubber compounds.

rubber antioxidants and chemical 6ppd

in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. in this review, we systematically review the recent progress of antioxidants for rubber.

analysis of rubber antioxidant tmq (rd) in different rubber

this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

rubber antioxidant tmq (rd) 26780-96-1 manufacturer,with its exceptional oxidation resistance, rubber antioxidant tmq is ideal for prolonging the lifespan of rubber products such as tires, rubber tubes, and cables. it protects against cracking, breaking, and becoming brittle, even in high-temperature and high-humidity conditions.

- What is rubber antioxidant TMQ / Rd?

- In the realm of rubber manufacturing, the utilization of effective rubber additives is crucial to ensure superior product quality and longevity. One such essential rubber additive is the Antioxidant TMQ, also known as RD.

- What is the role of TMQ in rubber product manufacturing?

- Role in Rubber Product Manufacturing: TMQ plays a pivotal role in various stages of rubber product manufacturing, offering a range of benefits to manufacturers: Oxidation Resistance: TMQ effectively inhibits the oxidation process, protecting rubber products from premature aging and degradation caused by exposure to heat, light, and oxygen.

- What is TMQ used for?

- It is widely used as a stabilizer and antioxidant in the rubber industry. TMQ acts as a protective agent against oxidative degradation, which occurs due to heat, oxygen, and other environmental factors. Its primary function is to inhibit the formation of harmful free radicals, thereby extending the service life of rubber products.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.