4010na rubber antioxidant: enhancing durability

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Rubber antioxidant

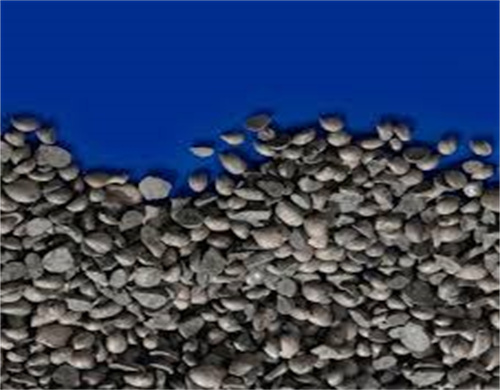

- Appearance:Amber to Brown Flake or Granular

- Specification:Customized

- Application:Leather Auxiliary Agents

- Production Capacity:200 Metric Tons per Month

- Package:25 kg/bag or as your require

factory priced rubber antioxidant ippd (4010na),factory priced rubber antioxidant ippd (4010na) , find complete details about factory priced rubber antioxidant ippd (4010na),best-selling rubber antioxidant,strong rubber antioxidant resistant to thermal oxygen aging,cas101-72-4 from rubber auxiliary agents supplier or manufacturer,It is particularly valued for its ability to enhance the durability and performance of tires, automotive belts, hoses, and other rubber goods.

4010na is a widely used rubber antioxidant that plays a crucial role in improving the durability and performance of rubber products. this article provides an in-depth overview of 4010na, highlighting its characteristics, applications in rubber product manufacturing, compatibility with other products, and essential cons

recent progress in the rubber antioxidants Rubber Auxiliary Agent

various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

rubber antioxidant ippd(4010na) rubber accelerator,ippd (4010na) rubber antioxidant, a high activity antioxidant for matural and synthetic rubber provides powerful antiozonant and antioxidant properties with excellent high temperature.

china rubber antioxidant 4010na manufacturers and suppliers

qinyang rodon chemical co., ltd. is a leading wholesale manufacturer and supplier of rubber antioxidant 4010na, a high-quality product designed to enhance the performance and lifespan of rubber materials.

synergistic effects of antioxidant and silica on enhancing,in this work, the thermo-oxidative aging performance of antioxidant n-isopropyl- n ′-phenyl- p -phenylenediamine (4010na)/silica (sio 2)/natural rubber (nr) composite was evaluated by the variations of mechanical properties and chemical structure after aging at 100 ℃.

rubber antioxidant 4010na ippd business products product detail

4-adpa is an intermediate product, mainly used for the production of p-phenylenediamine rubber anti-aging agent 4010na, 4020, etc.

antioxidant 4010na rubber auxiliary,natural rubber, synthetic rubber and latex with excellent general antioxidant, excellent protective properties of ozone cracking; also the heat, oxygen, light and aging two protective agent.

factory supply high quality rubber antioxidant ippd 4010na

general purpose anti aging agent, good protection against ozone and cracking item specifications product name rubber antioxidant 4010 na(ippd) appearance gray-purple to purplish brown granular purity€€%, ? 95.0 initial melting point€€℃, ? 70.0 heat loss€€%,€? 0.30 ash€€%, ? 0.20 application

classification and development status of rubber antioxidants,chemical antioxidant. the main antioxidants used in the rubber processing process are amine and quinoline antioxidants. the common types are antioxidant 4020,4010na and tmq. these three types...

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Does antioxidant 4010na and silica enhance thermo-oxidative aging assistance?

- In this work, the synergistic effects of antioxidant 4010NA and silica on enhancing thermo-oxidative aging assistance for NR were investigated by experiments and molecular simulations, and the mainly conclusions were generalized as follows:

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.