2024 professional guide to rubber antioxidant 6ppd

- Classification:Chemical Auxiliary Agent

- Purity:96%

- Type:Rubber antioxidant

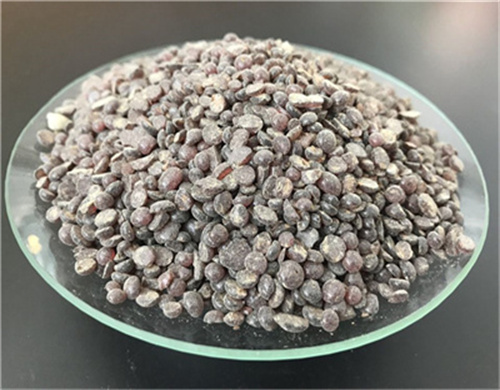

- Appearance:Gray Purple or Purple Brown

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Storage:Dry and Cooling Place

- Package:1000kgs/ pallet with film

antioxidant 6ppd price تست حامیکو,antioxidant 6ppd (4020) 6ppd is a strong antioxidant that is used as an antioxidant and antioxidation agent in rubber production. this substance has low toxicity and prevents polymer corrosion and increases the stability of the final product.

– rubber antioxidant 6ppd is mainly used as a rubber antioxidant in various rubber products such as tires, anti-skid materials, conveyor belts and so on. it can also be used as a catalyst for vulcanization of rubber products.

hot sale rubber antioxidant 6ppd for tyre/shoes

doi: 10.1021/acs.estlett.2c00187 corpus id: 248138015; hot sale rubber antioxidant 6ppd for tyre/shoes of the tire rubber antioxidant 6ppd (n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine)

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

6ppd rubber antioxidant: characteristics, applications

6ppd is an organic compound belonging to the p-phenylenediamine class of antioxidants. it is a dark purple solid with a slight odor. chemically, it consists of n- (1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine molecules. 6ppd is known for its solubility in rubber and compatibility with various types of rubber. 2.

tire manufacturers rubber antioxidant 6ppd,washington d.c.—the push to find an alternative to the tire antidegradant 6ppd—an additive that is critical to consumer safety but can transform into an offshoot chemical that is fatal to some fish species—continues for the u.s. tire manufacturers association.

rubber antioxidants tmq particles with best selling

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

end-of-life tire decontamination from 6ppd and upcycling nature,n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those found in tires. it.

hutchinson: 6ppd more than a pressing issue rubber news

there are many parameters to consider when seeking to substitute 6ppd, not least type of degradation—oxidation, ozone, fatigue or a combination of these, she said. a fundamental target here, she said, is to match the effectiveness of 6ppd in trapping hydrocarbon and peroxide radicals due to its high reactivity with ozone at rubber surfaces.

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

- Is 6PPD a toxic oxidant?

- To enhance tire durability, the antioxidant N- (1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine (6PPD) is used in rubber, but it converts into the toxic 6PPD quinone (6PPD-Q) when exposed to oxidants like ozone (O 3), causing ecological concerns.

- Can 6PPD be removed from end-of-life tires?

- We introduce a decontamination strategy that removes 6PPD from end-of-life tires before it enters the broader ecosystem. We demonstrate the catalytic upgrade of 6PPD to safe chemicals and the valorization of crumb rubber to aromatics and carbon black using microwave-assisted pyrolysis. You have full access to this article via your institution.

- Is 6PPD recalcitrant under harsh pyrolysis?

- This demonstrates the recalcitrant nature of 6PPD under harsh pyrolysis conditions and suggests solvent extraction is necessary for its removal. The TGA curve (Supplementary Fig. 11) of 6PPD shows a maximum degradation at ~300 °C and suggests that some 6PPD in the tires may sublime into the liquid product before the rubber degrades.

- What is the difference between 6PPD and real retinoids?

- Unlike the neat 6PPD, the real extract produced approximately 60% liquid (soluble in methanol) and 40% solid products. The only product made was 2,2,4-trimethyl-1,2,3,4-tetrahydroquinoline, a starting material for the synthesis of retinoids 37. See Supplementary Fig. 21 for more details.