rubber antioxidant 6ppd for tyre, belt

- Classification:Chemical Auxiliary Agent

- Purity:96.9%

- Type:Rubber additive antioxidant

- Appearance:Amber to Brown Flake

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Storage:Store in a Cool, Dry Place

- Package:Ply Kraft Paper Bag

6ppd chemical active antioxidant,6ppd is an organic chemical widely used as stabilising additive (or antidegradant) in rubbers, such as nr, sbr and br; all of which are common in vehicle tires. [1] although it is an effective antioxidant it is primarily used because of its excellent antiozonant performance. it is one of several antiozonants based around p-phenylenediamine. [2]

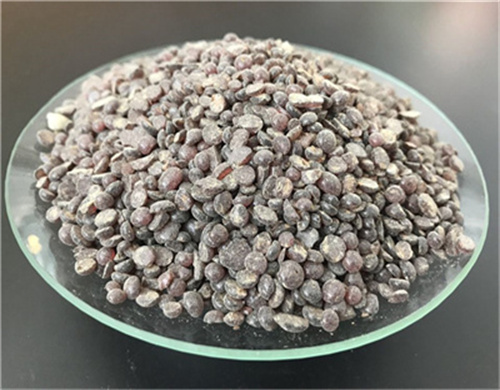

product name: rubber antioxidant 6ppd cas no.: 793-24-8 mf: c18h24n2 einecs no.: 212-344-0 appearance: dark purple granular

china rubber antioxidant 6ppd(4020) manufacturer, suppliers

as a professional china rubber antioxidant 6ppd(4020) manufacturer and suppliers, we supply rubber chemical, rubber additive as well as prepared rubber products with good price. this product is combustible, when storing and transporting, always pay attention to fireproof and dampproof.

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

screening p-phenylenediamine antioxidants, their

recently, roadway releases of n,n′-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers.

hot sale rubber antioxidant 6ppd for tyre/shoes,semantic scholar extracted view of "hot sale rubber antioxidant 6ppd for tyre/shoes of the tire rubber antioxidant 6ppd (n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine)" by ximin hu et al.

2024 professional guide to rubber antioxidant 6ppd

rubber antioxidant 6ppd is an additive that helps the rubber to resist degradation caused by the oxidation of its antioxidant. it is a highly effective solution for reducing the degradation of rubber products, especially those used in heavy machinery and transportation.

rubber antioxidants and their transformation products,rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . to date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

Rubber Antioxidant 6PPD 4020 from China supplier

as we advance into 2024, the role of antioxidants in rubber manufacturing remains crucial. one such critical antioxidant is n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine (6ppd). this article provides a comprehensive overview of 6ppd, comparing it with other rubber antioxidant types and discussing their applications in various industries.

end-of-life tire decontamination from 6ppd and upcycling nature,abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

- Which industrial rubber additives have higher chemical concentrations?

- Furthermore, we quantified 15 other industrial rubber additives (including bonding agents, vulcanization accelerators, benzotriazole and benzothiazole derivatives, and diphenylamine antioxidants), observing that PPD-derived chemical concentrations were 0.5–6 times higher than these often-studied additives.

- Is 6PPD recalcitrant under harsh pyrolysis?

- This demonstrates the recalcitrant nature of 6PPD under harsh pyrolysis conditions and suggests solvent extraction is necessary for its removal. The TGA curve (Supplementary Fig. 11) of 6PPD shows a maximum degradation at ~300 °C and suggests that some 6PPD in the tires may sublime into the liquid product before the rubber degrades.