rubber anti-aging agent 6ppd and its ozonation product 6ppdq.zghjkx

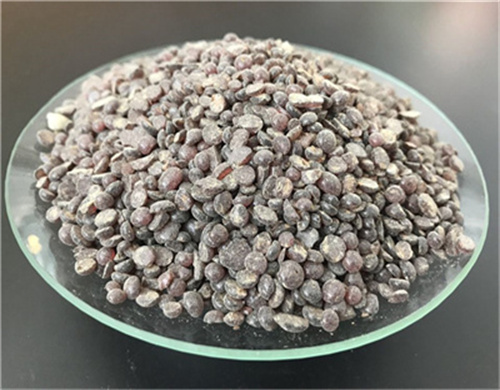

- Classification:Chemical Auxiliary Agent

- Purity:99.9%

- Type:Rubber antioxidant

- Appearance:Black Flake

- MOQ:1 ton

- Application:used in manufacture of tires

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

rubber anti-aging agent 6ppd and its ozonation product 6ppdq: environmental distribution and biological toxicity li jia-yao, shen hui-min, xu ting-ting, guo ying guangdong key laboratory of environmental pollution and health, school of environment, jinan university, guangzhou 510632, china

introduction of rubber antiaging agent and its types and functions

there are anti-aging agent ndbc, anti-aging agent ndibc, anti-aging agent ndmc. all green powder. with good ozone resistance and thermal oxidation resistance, expensive (due to nickel on the earth less storage, but a wide range of uses), but also a certain toxicity, deep color, easy to spray frost, not suitable for light color rubber products, in the rubber industry consumption is very few.

rubber antioxidant tmq supplier,rd is an excellent kind of general-purpose ammonia anti-aging agent. it is particular suit to full-steel, semi-steel radial tyre. also apply to many kinds of tires, rubber tubes, gummed tape rubber overshoes and general industrial rubber products. suits to emulsion

recent progress in the rubber antioxidants price

in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

commonly used rubber anti aging agent knowledge shenyang,d. derivatives of p-phenylenediamine, this kind of anti-aging agent is currently widely used in the rubber industry.they can inhibit the ozone aging, fatigue aging, thermal oxygen aging and metal ion catalytic oxidation of rubber products.(e.g. uop788).this kind of

surface behaviors of epdm rubber and mechanism of nano anti-aging agent

based on ultraviolet (uv) accelerated aging tests, aging processes were tracked to study the effects of nano-tio2 antiaging agent on the surface aging behaviors and anti-aging ability of ethylene-propylene-diene monomer (epdm). the anti-aging mechanism was also analyzed by fourier transform infrared spectroscopy (ft-ir) and uv absorption spectroscopy. when the aging time prolongs.

antioxidant modified graphene oxide for robust and highly aging,in this work, rubber antioxidant poly(1,2-dihydro-2,2,4-trimethylquinoline) (rd) was introduced as organic surface modifier of graphene oxide (go) for the preparation of robust and highly anti-aging rubber composites.it was found that rd was chemically grafted on go surface by c–n bond. by c–n bond.

facrory supply anti-aging agent, tmq, 6ppd, ippd production lead

ketone amine anti-aging agent. has the best anti-aging effect. there are: anti-aging agent rd, anti-aging agent aw, anti-aging agent ble. diaryl secondary amine anti-aging agent. this is one of the old varieties. it is still the first among all anti-aging agents

synthesis and properties of a novel reactive and low-migration,the addition of antioxidants to rubber is one of the most economical and effective methods for delaying rubber aging. however, antioxidant migration can cause environmental pollution. to address this issue, a new reactive antioxidant was synthesized via the chemical bonding of glycidyl methacrylate (gma) and p-aminodiphenylamine (ppda). the product was characterized by fourier-transform.

- Can antioxidants prevent rubber aging?

- The addition of antioxidants to rubber is one of the most economical and effective methods for delaying rubber aging. However, antioxidant migration can cause environmental pollution. To address this issue, a new reactive antioxidant was synthesized via the chemical bonding of glycidyl methacrylate (GMA) and p -aminodiphenylamine (PPDA).

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Do antioxidants and their TPS increase environmental risk awareness of rubber products?

- To our knowledge, this is the first review on antioxidants and their TPs in the environment, which may elevate the environmental risk awareness of rubber products and their TPs in the near future.

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.