tmq antioxidant for rubber industry: enhancing performance

- Classification:Chemical Auxiliary Agent

- Purity:96.0% MIN

- Type:Anti-aging agent

- Appearance:Grey purple to purple brown

- Selling Units:Single item

- Application:used in rubber shoes and other rubber products

- Production Capacity:200 Metric Tons per Month

- Package:25 kg/bag or as your require

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

in the realm of rubber manufacturing, the utilization of effective rubber additives is crucial to ensure superior product quality and longevity. one such essential rubber additive is the antioxidant tmq, also known as rd. in this article, we will delve into what tmq is, its role in rubber product production, and the advantages it holds over other similar products in the market. tmq antioxidant.

the anti-aging agent, tmq, 6ppd, ippd production lead

it includes the most important type of anti-aging agent, and it is also a promising anti-aging agent. there are: anti-aging agent 4010na/ippd, anti-aging agent 4020/6ppd, anti-aging agent 4010/cppd, anti-aging agent oda, anti-aging agent dppd, anti-aging

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

insight into the anti-aging mechanisms of natural phenolic antioxidants

Trends in Antioxidant Antiaging Effects The trends in antioxidant antiaging effects can be predicted and quantitatively calculated as described in the following sections. Dissociation Free Energy. As shown in Figure 2, the bonds of rubber macromolecules are easily broken because of their large bond lengths.

2023 professional guide to rubber antioxidant tmq,rubber antioxidant tmq is a chemical compound that has been shown to be have any questions? This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

rubber anti aging agent tmq provider, supplier, manufacturer rubber

please contact us for more information about rubber anti aging agent tmq, trading and rubber anti aging agent tmq quote. supplier tin phu chemical tin phu trading production company limited

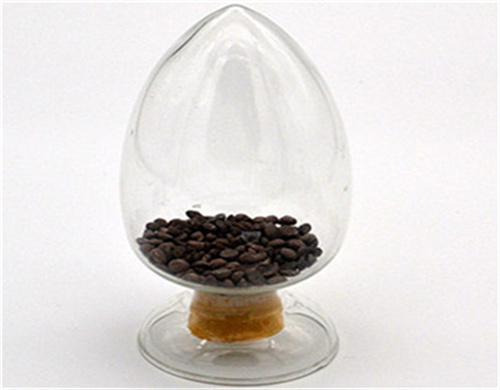

rubber antioxidant tmq price rubber antioxidant products,appearance of the product: colored lentil granules. type of packaging: bag. weight of each bag: 25 kg. country of manufacture: china. existing brand: henan kailun. download catalog. download datasheet. antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging.

anti-aging agent rd china antioxidant tmq and antioxidant

cas no.: 26780-96-1 certification: ccic, reach color: amber to brown kind: antioxidant appearance: granulars melting point: 80-100ºc

recent progress in the rubber antioxidants price,this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. the oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism [1]. as shown in fig. This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

- What is antioxidant TMQ?

- Antioxidant TMQ is a widely used antioxidant, especially used in the rubber industry. Similar to other antioxidants, TMQ acts as an anti-aging agent and protects rubber from heat and heat. Antioxidants are substances that hinder oxidation. Antioxidants play a role in protecting the polymer from degradation during the production of rubber.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- How can Antioxidants improve the antioxidative capacity of the rubber matrix?

- Generally speaking, as shown in Figs. 2 and 3, there are two main strategies to improve the antioxidant's antioxidative capability for the rubber matrix: (i) using two or more antioxidants together, and (ii) molecular design of antioxidants. Fig. 2.

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].