commonly used rubber anti aging agent knowledge shenyang

- Classification:Chemical Auxiliary Agent

- Purity:99.9%

- Type:Rubber chemicals

- Appearance:Granulars/Flakes

- Boiling point:260°C

- Application:For ethylene propylene, etc.

- Production Capacity:50000000t/Year

- Package:25 kg plastic woven bag

recent progress in the rubber antioxidants price,this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. the oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism [1]. as shown in fig. This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

d. derivatives of p-phenylenediamine, this kind of anti-aging agent is currently widely used in the rubber industry.they can inhibit the ozone aging, fatigue aging, thermal oxygen aging and metal ion catalytic oxidation of rubber products.(e.g. uop788).this kind of

rubber aging agent 6ppd (4020) national standard quality rubber

rubber aging agent 6ppd(4020) national standard quality rubber additives high efficiency anti aging rubber antioxidant 4020/6ppd chemical name:n-(1,3-dimethyl-buty)-n’-phenyl-p-phenylenediamine molecular: c18h24n2 cas no.: 793-24-8 : 268.40 price.

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

antioxidant modified graphene oxide for robust and highly aging

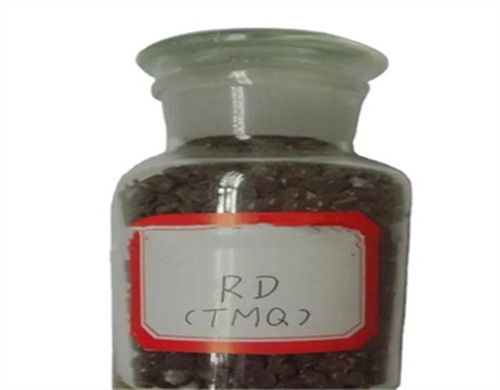

in this work, rubber antioxidant poly(1,2-dihydro-2,2,4-trimethylquinoline) (rd) was introduced as organic surface modifier of graphene oxide (go) for the preparation of robust and highly anti-aging rubber composites.it was found that rd was chemically grafted on go surface by c–n bond. by c–n bond.

anti-aging agents for rubber products supplier,there aremany kinds of antioxidants for rubber products, and each antioxidant has several anti-aging effects at the same time. according to the chemical structure, they can be divided into: amines.

chinese anti-aging agent 4020 suppliers, manufacturers, and traders

6、the antioxidant activity of anti-aging agent 4020 is higher than that of quinoline or diphenylamine antioxidants. make the rubber has good resistance to copper and other heavy metal catalytic degradation performance. 7、anti-aging agent 4020 will discolor the

synthesis and properties of a novel reactive and low-migration,the addition of antioxidants to rubber is one of the most economical and effective methods for delaying rubber aging. however, antioxidant migration can cause environmental pollution. to address this issue, a new reactive antioxidant was synthesized via the chemical bonding of glycidyl methacrylate (gma) and p-aminodiphenylamine (ppda). the product was characterized by fourier-transform.

antioxidant effects on curing/processing and thermo-oxidative aging of

in order to delay the aging process of the diene elastomer, chemical antioxidants, such as derivatives of aromatic, are usually added into the elastomer to capture free radicals. these antioxidants can significantly improve the thermo-oxidative stability of rubber [[18], [19], [20]].].

computational studies of rubber ozonation explain the effectiveness of,this and other pressures have led the development of highly effective rubber additives that protect rubber from degradation during manufacture and use, most notably p-phenylenediamines (ppds). (3,4) among these, 6ppd ( n -(1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine) in particular has gained ubiquity in the tire industry and is included at 0.5–1.5 wt % in standard formulations.

- Are rubber antioxidants effective against aging and antimigration?

- The antiaging and antimigration properties of the rubber antioxidants were enhanced without damaging the mechanical properties of the rubber matrix. The short-term and long-term antiaging and antimigration properties of this antioxidant are superior to those of commercially available antioxidants. CC-BY-NC-ND 4.0 . 1. Introduction

- What is oxidative aging of rubber?

- Thermal oxidative aging is the most frequent type of rubber degradation. To delay or prevent this process, antioxidants can be added to rubber compounds during mixing. (9) Antiaging agents react primarily with the free radicals or hydrogen peroxide generated during rubber aging.

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.