rubber antioxidant 6ppd for tyre, belt

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Rubber additive antioxidant

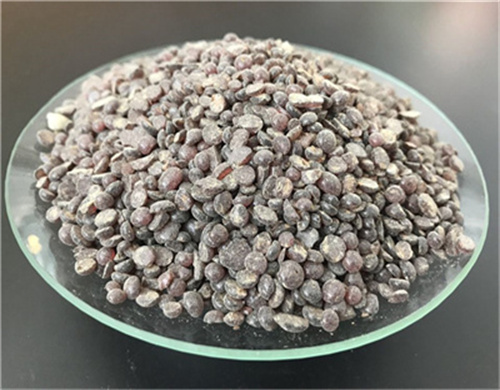

- Appearance:Dark brown to dark vilet pastilles or flake

- MOQ:1 ton

- Application:used in manufacture of tires

- Production Capacity:200 Metric Tons per Month

- Package:25 kg/bag or as your require

screening p-phenylenediamine antioxidants, their,recently, roadway releases of n,n′-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers.

product name: rubber antioxidant 6ppd cas no.: 793-24-8 mf: c18h24n2 einecs no.: 212-344-0 appearance: dark purple granular

antioxidants rubber antioxidant 4020 6ppd, grade standard

vpr rubber offering antioxidants rubber antioxidant 4020 6ppd, grade standard: industrial grade, packaging size: 25 at rs 320/kg in new delhi, delhi. also find rubber antioxidants price list id: 26902943333

screening p-phenylenediamine antioxidants, their,recent evidence indicated the heterogeneous reaction of gas-phase ozone with the precursor of 6ppd-q, a widely adopted tire rubber antioxidant named 6ppd, thus yielding a range of tps including.

end-of-life tire decontamination from 6ppd and upcycling nature

abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

a ubiquitous tire rubber–derived chemical induces acute,by investigating this phenomenon, we identified a highly toxic quinone transformation product of n-(1,3-dimethylbutyl)-n′-phenyl-p-phenylenediamine (6ppd), a globally ubiquitous tire rubber antioxidant. retrospective analysis of representative roadway runoff and stormwater-affected creeks of the u.s. west coast indicated widespread occurrence.

rubber antioxidant agent 6ppd(4020) rubber accelerator

properties: pure 6ppd is white solid product, and will gradually oxidizing to brown solid when exposed to the air.industrial product—6ppd is purple brown to black brown granules or flakes, and will slowly caking when the temperature exceeds 35-40℃.soluble in gasline, benzene, acetone, ethyl acetate, dichloroethane, carbon tetrachloride ,methylbenzene, ethylalcohol and other organic.

screening p-phenylenediamine antioxidants, their,screening p‑phenylenediamine antioxidants, their transformation products, and industrial chemical additives in crumb rubber and elastomeric consumer products haoqi nina zhao, ximin hu, melissa gonzalez, craig a. rideout, grant c. hobby, matthew f. fisher, carter j. mccormick, michael c. dodd, kelly e. kim, zhenyu tian,* and edward p. kolodziej*

screening p-phenylenediamine antioxidants, their

recently, roadway releases of n,n'-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of 6ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers for.

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

- Are p phenylenediamine (PPD) antioxidants in recycled tire rubber products toxic?

- Recently, roadway releases of N, N ′-substituted p -phenylenediamine (PPD) antioxidants and their transformation products (TPs) received significant attention due to the highly toxic 6PPD-quinone. However, the occurrence of PPDs and TPs in recycled tire rubber products remains uncharacterized.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- What is the antioxidative effect of silica-s-TP for rubber composite?

- The antioxidative effect of silica-s-TP for rubber composite is superior to for the traditional antioxidants such as 4020, RD, 2246 and 264, and the high efficiency free radical capturing activity of silica-s-TP was stem from the polyphenol on the silica surface.