2024 professional guide to rubber antioxidant tmq

- Classification:Chemical Auxiliary Agent

- Purity:97.%

- Type:Rubber antioxidant

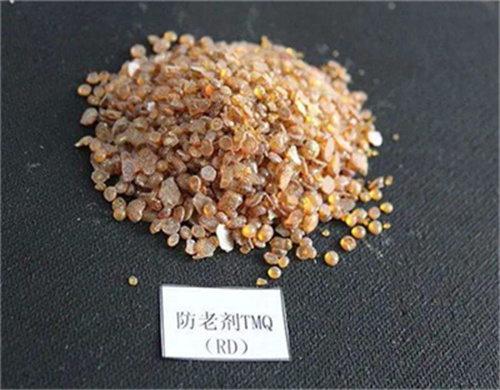

- Appearance:Dark brown to dark vilet pastilles or flake

- Place of Origin:Henan, China

- Application:Rubber Industry

- Production Capacity:200 Metric Tons per Month

- Package:25 kg/bag or as your require

recent progress in the rubber antioxidants price,the commonly used rubber antioxidant can be divided into primary antioxidant and secondary antioxidant according to the anti-aging mechanism [13]. the primary antioxidants, such as aryl amines and phenolic antioxidants, could inhibit the propagation reaction by supplying the reactive hydrogen atom to the free radicals.

rubber antioxidant tmq is a high-quality rubber stabilizer that helps to increase the life of synthetic rubber and natural rubber. the product is produced by mixing the rubber antioxidant with other additives to form a homogeneous mixture, which is then applied to the surface of rubber products.

novel antioxidants based on polymerized 2,2,4-trimethyl-1,2

the formed triazoles are found to have good antioxidant efficiency . due to the strong antioxidant activity of hydrazide, 1,3,4-oxadiazoles and 1,2,4-triazoles, our goal is to study the chemical modification of tmq (commercial antioxidant for rubber) by insertion of hydrazide, 1,3,4-oxadiazole and 1,2,4-triazole moieties to its backbone.

insight into the anti-aging mechanisms of natural phenolic,insight into the anti-aging mechanisms of natural phenolic antioxidants in natural rubber composites using a screening strategy based on molecular simulation† ling lu,a kaiqiang luo,a wei yang,b sidian zhang,a wencai wang, a haiyan xu *c and sizhu wu *a the failure of materials upon aging has led to the accumulation of waste and environmental.

rubber antioxidants and their transformation products

rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . to date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

an alternative antioxidant for sulfur-vulcanized natural,this study aims to study the effect of adding crepe rubber and the antioxidant 1,2-dihydro-2,2,4-trimethyl-quinoline (tmq) to the marshall characteristics of rubber asphalt.

antioxidant rd (tmq) (high) chemical supplier

antioxidant rd (tmq) (high) by kemai chemical is 2, 2, 4-trimethyl-1, 2-dihydroquinoline. it acts as an antioxidant. it can be used as a general purpose ammonia anti aging agent. it is suitable for full-steel, semi steel and radial tires.

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

rubber antioxidant tmq(rd) (high-class) technical datasheet

rubber antioxidant tmq(rd) (high-class) by henan rtenza is 2,2,4-trimethy1-1,2-dihydroquinoline grade. it acts as a rubber antioxidant. it provides heat and anti-aging resistance. rubber antioxidant tmq(rd) (high-class) is suitable for tires, rubber tubes, gummed tapes, rubber overshoes and general industrial rubber products.

analysis of rubber antioxidant tmq (rd) in different rubber,this paper provides an in-depth analysis of rubber antioxidant tmq (rd)'s application in various rubber products, highlighting its anti-aging benefits and improving performance in all-steel and semi-steel radial tires, hoses, and belts.

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- Does TMQ prevent rubber oxidation?

- This study’s optimal TMQ level was 2%, with a decrease in penetration after RTFOT of only 10–15%. TMQ can prevent rubber oxidation in 2 ways: stabilizing free radicals or scavenging free radicals and the second by inhibiting peroxide formation [ 2 ].

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Does antioxidant 2246 protect rubber from aging?

- Among them, antioxidant 2246 has a good performance to protect rubber from aging caused by heat, oxygen, and metals. Because hydrogen in phenolic antioxidants can combine with the oxygen in air, their antiaging efficiency is therefore lowered compared with amine antioxidants [21, 22].