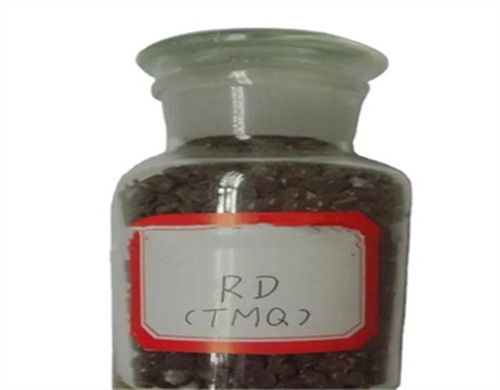

rubber antioxidant tmq (rd) manufacturer

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Rubber chemicals

- Appearance:Grayish purple to purple brown granular

- Place of Origin:Henan, China

- Application:Rubber Industry

- Storage:Cool Dry Place

- Package:25 kg/bag,1000 kg/bag,customized packaging

south korea: rubber antioxidant domestic demand 2022 statista,in 2022, domestic demand for rubber antioxidant in south korea reached over 16,000 metric tons. rubber antioxidant is used to prolong the lifecycle of rubber products by delaying...

with its exceptional oxidation resistance, rubber antioxidant tmq is ideal for prolonging the lifespan of rubber products such as tires, rubber tubes, and cables. it protects against cracking, breaking, and becoming brittle, even in high-temperature and high-humidity conditions.

rubber antioxidants and chemical 6ppd

in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

rubber antioxidant tmq/rd 1ton cost,rubber antioxidant tmq/rd. find product specification, supplier information and more at tradekorea

kumho specialty rubber chemicals kkpc.com

- provides excellent antioxidant and antiozonant properties with protection against oxidation, ozone attack, heat aging, fatigue, flexcracking and metal poisons to rubber goods. gives higher rubber solubility due to its good dispersion in rubber compounds. main uses : tires, belts, hoses, cables, automotive mounts and goods for industrial uses.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,various external factors, including oxidative agents (such as oxygen), heavy metals, uv rays, ozone, mechanical stress, heat, and aggressive chemicals, etc., could accelerate rubber aging. this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers.

antioxidant rd(tmq) for rubber industry 1ton cost

antioxidant rd(tmq) for rubber industry. find product specification, supplier information and more at tradekorea

study on the industrial process of rubber anti-oxidant rd,rubber anti-oxidant rd polymer mixture is a so-called dihydro-quinoline polymer, produced by a reac-tion between aniline and acetone, which are widely used for heat aging resistance, since they are not only superior in preventing heat aging but also cheaply available.

global rubber antioxidant rd supply, demand and key producers

antioxidant rd is 2,2,4-trimethyl-1,2-dihydroquinoline polymer-based primary antioxidant in dry rubber application. it maintains physical and surface properties with good color, very good anti-scorch as well as good heat resistance.

technical data sheet (tds) with high quality,application: tmq (rd) is a very important rubber antioxidant. it is suit to all-steel, semi-steel radial tire and widely used in the manufacture of tires, rubber tube, adhesive tape, wires, cables and other industrial rubber products. package: net weight: 25kg/bag, packed in paper bag lined with plastic bag.

- What is rubber anti-oxidant Rd polymer mixture?

- Rubber Anti-oxidant RD polymer mixture is a so-called dihydro-quinoline polymer, produced by a reac- tion between aniline and acetone, which are widely used for heat aging resistance, since they are not only superior in preventing heat aging but also cheaply available.

- What is rubber anti oxidant Rd?

- Rubber Anti- oxidant RD has a longer-time remaining of protective effect, because it has a higher molecular weight and has little diffusive loss. So it is suitable for the rubber prod- ucts used in tropical area.

- How does rubber antioxidant work?

- To prolong the service life of rubber composites by retarding their aging processes, rubber antioxidant initially relies on the use of a coating, such as paraffin, and coal tar, to physically isolate oxygen, but this protective layer would quickly lose the utility due to wear.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.