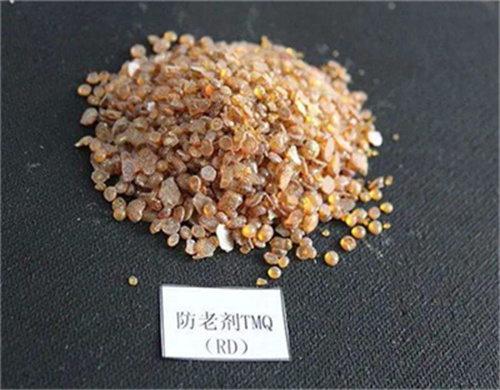

rubber antioxidant tmq with best price

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Rubber antioxidant

- Appearance:Gray Purple or Purple Brown Granular

- Shelf life:2 Years

- Application:Plastic Auxiliary Agents

- Production Capacity:10000 Kilogram/Kilograms per Day

- Package:As the client's request

rubber antioxidants and their transformation products,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental

rd is an excellent kind of general-purpose ammonia anti-aging agent. it is particular suit to full-steel, semi-steel radial tyre. also apply to many kinds of tires, rubber tubes, gummed tape rubber overshoes and general industrial rubber products. suits to emulsion products too.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

recent progress in the rubber antioxidants Rubber Auxiliary Agent,the anti-aging behavior of styrene-butadiene rubber (sbr)/silica with cos-gmmp, as well as the low molecule antioxidant gm, was systematically investigated by the accelerated thermal aging...

application of antioxidant dtpd/3100 in rubber industry

antioxidant dtpd (also known as antioxidant 3100) is a widely used antioxidant in the rubber industry, mainly used to improve the aging resistance of rubber products. the following are the main applications and characteristics of dtpd in the rubber industry:

synthesis and properties of a novel reactive and low,thermal oxidative aging is the most frequent type of rubber degradation. to delay or prevent this process, antioxidants can be added to rubber compounds during mixing. antiaging agents react primarily with the free radicals or hydrogen peroxide generated during rubber aging.

Factory Hot Sale Rubber antioxidant In Stock

in this study, we chose natural rubber (nr) as a matrix and provided a screening strategy based on diverse natural phenolic antioxidants to evaluate their ability in protecting nr composites. thymol, α-tocopherol, and lipid-soluble epigallocatechin gallate (lsegcg) were chosen from 18 natural phenolic antioxidants as potential alternative

rubber antioxidants and chemical 6ppd,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental

Factory Hot Sale Rubber antioxidant In Stock

the complexity of thermo-oxidative aging factors along with the lack of quantitative tools significantly hampers its applications. so, building a screening strategy to quickly and easily find an appropriate and eco-friendly ao is imperative. in this study, we chose natural rubber (nr) as a matrix and provided

biomass antioxidant silica supported tea polyphenols with,our previous study demonstrated that chemically supported rubber anti-aging agents on nanofiller surface could availably resolve the problem of mobility and significantly improve the anti-aging performance, such as supported 2-mercaptobenzimidazole (mb) on silica surface [16] and simultaneously reduce and functionalize graphene oxide (go) via n

- Can antioxidants prevent rubber aging?

- The addition of antioxidants to rubber is one of the most economical and effective methods for delaying rubber aging. However, antioxidant migration can cause environmental pollution. To address this issue, a new reactive antioxidant was synthesized via the chemical bonding of glycidyl methacrylate (GMA) and p -aminodiphenylamine (PPDA).

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.

- What are the TPS of rubber antioxidants?

- The TPs of rubber antioxidants have been observed in some studies under environmental conditions. As one of the widespread rubber antioxidants, amine antioxidants (PPDs: TMPPD, DPPD, 6PPD, and 6PPDTZ) could react with O 3 (in parts per billion volume levels) in the environment and produce PPD-quinone .

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.