recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:96.0% MIN

- Type:Anti-aging agent

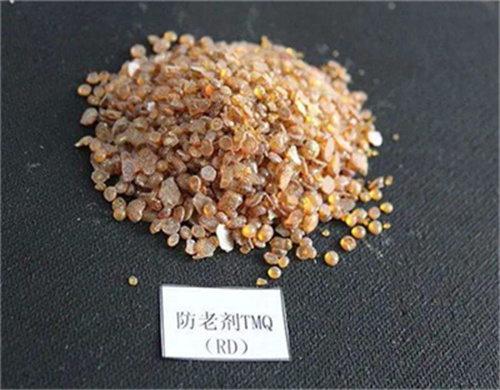

- Appearance:Dark brown, dark violet pellet

- Content:95%

- Application:Shoe Soles, auto tyre

- Production Capacity:100000 Metric Ton per Year

- Package:25kg/bag, OEM

recent progress in the rubber antioxidants Rubber Auxiliary Agent,after 168 hours of thermal oxidative aging test at 100℃, styrene‐butadiene rubber with 10 wt % surface thiol functionalized mesoporous silica nanorods loaded with 4020 (msn‐sh‐4020) shows

the rubber antioxidant market is expected to expand significantly in the future due to the increasing demand for antioxidants in the manufacture of various rubber products used in the tire industry, automotive industry, and others.

rubber antioxidants and their transformation products

recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

enhancing tire durability: application analysis of rubber,this article focuses on the application of rubber antioxidant 6ppd (4020) in improving tire durability, revealing its specific mechanism of antioxidant and anti-aging, as well as its significant effects in practical applications.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

in this review, we systematically review the recent progress of antioxidants for rubber. we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants.

rubber antioxidants and chemical 6ppd,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

rubber antioxidant manufacture 6ppd4020 granular for tyre

stormwater is a major source of trwps and associated additives to urban surface water, with additives including the antioxidant derivative n-(1,3-dimethylbutyl)-n¡ä-phenyl-p

improvement of tire durability using rubber antioxidant 6ppd,discover how the application of rubber antioxidant 6ppd (4020) can significantly enhance tire durability, performance, and safety. learn about the benefits of using 6ppd, including extended tire life and improved resistance to high temperature and humidity conditions, making it an ideal choice for tire manufacturers aiming to improve product

rubber antioxidants and their transformation products

in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

rubber antioxidant 6ppd (4020) a must-have for improving,rubber antioxidant 6ppd (4020) is a highly efficient multi-purpose antioxidant with excellent antioxidant and high temperature resistance properties. it can significantly improve the durability and protective effect of rubber products, and is especially suitable for complex and harsh dynamic working conditions. .

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].

- Are rubber antioxidants toxic?

- Recent advances in the toxicity issue of rubber antioxidant With the increasing popularity of automobiles, tire wear particles, generated from tire material during use on roads, would ultimately enter the eco-system, such as soil, aquatic environment, etc .

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.