recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Anti-aging agent

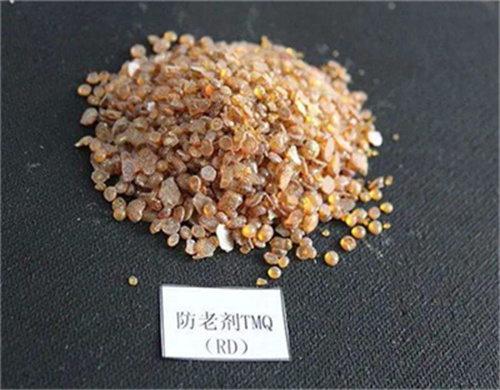

- Appearance:Purple brown to dark brown granules or flakes

- Melting Point:45.0℃

- Application:For natural rubber

- Production Capacity:50000000t/Year

- Package:25 kg plastic woven bag

antioxidant sustained release from carbon nanotubes for,In this work, a new strategy is proposed to avoid antioxidant blooming and improve the aging resistance of styrene butadiene rubber (SBR), using carbon nanotubes (CNTs) loaded with antioxidant N-(1,3-dimethyl)butyl-N′-phenyl-p-phenylenediamine (4020) as filler.

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

rubber antioxidants and chemical 6ppd

in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

rubber antioxidant 4020(6ppd) with high quality,6ppd is a polluting antioxidant. in addition to having good anti oxygen effect, it also has the functions of anti ozone, anti bending and cracking, and inhibiting harmful metals such as copper and manganese. cas no. 793-24-8. formula.

Hot Selling Rubber Anti Aging Agent Rubber Antioxidant 6PPD

lanxess chemical rubber antioxidant 4020/lg rubber antioxidant categories: other engineering material; additive/filler for polymer. material notes: aging processes, which are caused by oxygen or heat, change the properties of the vulcanizates.

the use of crude carbon dots as novel antioxidants for,for comparison, the nr/antioxidant 4020 composites were also prepared. the curing characteristics (e.g., maximum torque m h, minimum torque m l, scorch time t 10, and optimum cure time t 90) for the rubber samples were determined by a vulcameter.

rubber antioxidant 4020 grade sinorgchem

rubber antioxidant 4020 grade by specialchem. share. download rubber antioxidant 4020 grade. technical datasheet supplied by sinorgchem read more view less

synthesis and properties of a novel reactive and low,rubber composites containing antioxidants 4020 and 4010na were immersed and extracted, resulting in solutions that were noticeably darker in color than those of the rubber composites with gma-ppda antioxidants, which had also been immersed.

rubber antioxidant 6ppd (4020) (high-class) with best quality

it offers antioxidant properties with excellent high temperature and flexing resistance to rubber compounds. rubber antioxidant 6ppd(4020) (high-class) is suitable for applications including solid tires, conveyors, hoses, cables, bushings, automotive mounts and general rubber products.

rubber antioxidants and their transformation products,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- What are the TPS of rubber antioxidants?

- The TPs of rubber antioxidants have been observed in some studies under environmental conditions. As one of the widespread rubber antioxidants, amine antioxidants (PPDs: TMPPD, DPPD, 6PPD, and 6PPDTZ) could react with O 3 (in parts per billion volume levels) in the environment and produce PPD-quinone .

- Does antioxidant 2246 protect rubber from aging?

- Among them, antioxidant 2246 has a good performance to protect rubber from aging caused by heat, oxygen, and metals. Because hydrogen in phenolic antioxidants can combine with the oxygen in air, their antiaging efficiency is therefore lowered compared with amine antioxidants [21, 22].