recent progress in the rubber antioxidants Rubber Auxiliary Agent

- Classification:Chemical Auxiliary Agent

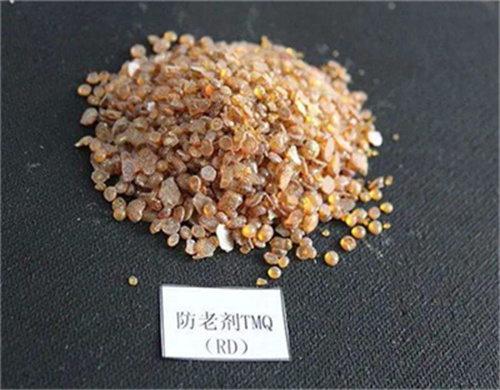

- Purity:96.9%

- Type:Rubber antioxidant

- Appearance:Amber to Brown Flake

- Characteristic:Accelerated curing

- Application:Rubber goods/plastic/shoes/tyre

- Production Capacity: 500 Metric Tons per Month

- Package:25kg in kraft paper bag with PE bag inside

the effect of antioxidant concentration of n-isopropyl-n,tools. study the influence of high concentrations of antioxidants n-isopropyl-n-phenyl-p-phenylenediamine (ippd) and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq) and the mixing time of the vulcanization physical properties, thermal properties, mechanical properties and structure micro on natural rubber compound has been done.

we first give a brief introduction of the oxidation process and oxidation mechanism for rubbers. then, we present the strategies to improve the anti-oxidative efficiency of rubber antioxidants. after that, recent advances to minimize the blooming and migration of antioxidants are summarized.

tmq rubber antioxidant for tyre manufactures and rubber

an antioxidant for natural rubber and many kinds of synthetic rubber, especially for the prevention of thermal deterioration on nbr. these goods can be used in heated vessels and the torrid zone. usage: nr, nbr etc.

rubber antioxidant tmq (rd) 26780-96-1 manufacturer,with its exceptional oxidation resistance, rubber antioxidant tmq is ideal for prolonging the lifespan of rubber products such as tires, rubber tubes, and cables. it protects against cracking, breaking, and becoming brittle, even in high-temperature and high-humidity conditions.

transformation products of tire rubber antioxidant 6ppd for sale

6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppd), 6PPD is compatible with a wide range of rubber types, including natural rubber and various synthetic rubbers, making it versatile for different formulations.

rubber antioxidants and chemical 6ppd,in this review, we first summarize the category and application of rubber antioxidants in the world, and then demonstrate the formation mechanism of their tps in the environment, emphasizing their influence on the ozone oxidative degradation.

rubber antioxidant tmq for sale products

antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat.

tmq antioxidant for rubber industry: enhancing performance,tmq, the antioxidant rd, is a vital additive in the rubber industry, safeguarding rubber products from premature aging and degradation. with its exceptional antioxidative properties, tmq enhances the durability, heat resistance, and flexibility retention of rubber compounds.

Factory Hot Sale Rubber antioxidant In Stock

in this study, we chose natural rubber (nr) as a matrix and provided a screening strategy based on diverse natural phenolic antioxidants to evaluate their ability in protecting nr composites. thymol, a-tocopherol, and lipid-soluble epigallocatechin gallate (lsegcg) were chosen from 18 natural phenolic antioxidants as potential alternative

novel antioxidants based on polymerized 2,2,4-trimethyl-1,2,the formed polymers are evaluated as antioxidants for styrene-butadiene rubber (sbr) composites. tmq and the prepared polymers are added to sbr by a concentration of 1 phr and their antioxidant activity is compared.

- Do antioxidants and their TPS increase environmental risk awareness of rubber products?

- To our knowledge, this is the first review on antioxidants and their TPs in the environment, which may elevate the environmental risk awareness of rubber products and their TPs in the near future.

- What are the different types of antioxidants in rubber?

- Chemical antioxidants are generally classified as amine, phenolic, heterocyclic, phosphite, and nickel salts (nickel dibutyl dithiocarbamate (NBC)) antioxidants according to their chemical structure (Figure 1). During the rubber production, various antioxidants are often used as a mixture to improve performance and ensure an antiaging effect.

- What is TMQ polymerization reaction?

- First, the condensation reaction (R1) is carried out under acid conditions, which converts aniline (A) and acetone (B) to the TMQ monomer (C) and water (D). Then polymerization reactions (R2 − R4) are conducted, in which the monomers (C) are polymerizes to TMQ oligomers including dimers (E), trimers (F) and tetramers (G). (R1)(R2)(R3)(R4)

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.