rubber antioxidant 4020 6ppd for Tyres

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Anti-aging agent

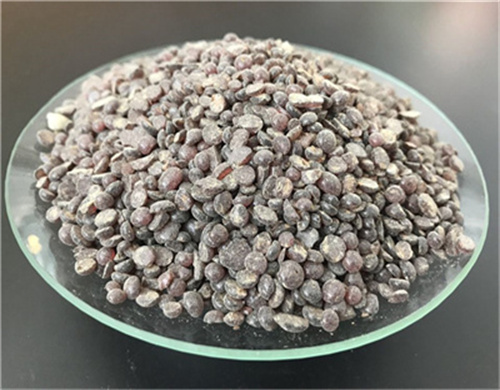

- Appearance:Gray Purple or Purple Brown Granular

- MOQ:1 ton

- Application:used in manufacture of tires

- Production Capacity: 500 Metric Tons per Month

- Package:25kg in kraft paper bag with PE bag inside

rubber antioxidants and their transformation products,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

Rubber antioxidant 4020. Chemical name: N-(1,3-dimethylbutyl)-N-phenyl-p-phenylenediamine. Molecular formula: C18H24N2. Molecular weight: 268.4. It can soften sizing material, so can be used for tires and other kinds of rubber products, also can be used as heat oxygen stabilizer for polyethylene, polypropylene and acrylic resin.

rubber antioxidant 4020 request for quotation supplier

it is an antiozonant and antioxidant for natural rubber and synthetic rubber, and has excellent protective effect against ozone cracking and flex fatigue. production method. a variety of methods can be used to prepare antioxidant 4020.

rubber aging agent 6ppd(4020) national standard quality,Detailed introduction. Rubber antioxidant 4020/6PPD. Chemical name: N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine. Molecular formula: C18H24N2. CAS number: 793-24-8. Molecular weight: 268.40. 6PPD is a phenylenediamine rubber antioxidant with good compatibility with rubber, not easy to bloom, low volatility and low toxicity.

Hot Selling Rubber Anti Aging Agent Rubber Antioxidant 6PPD

lanxess chemical rubber antioxidant 4020/lg rubber antioxidant. aging processes, which are caused by oxygen or heat, change the properties of the vulcanizates. rubbers generally are subject to such changes that occur in the course of time and can lead to partial or complete destruction.

Rubber Antioxidant 6PPD technical data sheet,technical data sheet (tds) chemical name: n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine. other name: 4020. molecular formula: c18h24n2.

rubber antioxidant 6ppd (4020) (high-class) with best quality

rubber antioxidant 6ppd (4020) (high-class) by henan rtenza is n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine grade. it offers antioxidant properties with excellent high temperature and flexing resistance to rubber compounds.

buy wholesale rubber antioxidants in kenya rubber,find the best kenya rubber antioxidants and explore our extensive collection of high-quality rubber antioxidants from kenya. buy wholesale rubber antioxidants in kenya from trusted suppliers.

rubber antioxidant 6ppd (4020) a must-have for improving

rubber antioxidant 6ppd (4020) is a highly efficient multi-purpose antioxidant with excellent antioxidant and high temperature resistance properties. it can significantly improve the durability and protective effect of rubber products, and is especially suitable for complex and harsh dynamic working conditions. .

recent progress in the rubber antioxidants Rubber Auxiliary Agent,therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. in this review, we systematically review the recent progress of antioxidants for rubber.

- Can rubber antioxidants contain rare-earth ions?

- The recently reported rubber antioxidants containing rare-earth ions are summarized in Fig. 4, for instance, Sun et al. prepared a novel hindered phenol rare-earth complex (DTSm) (Fig. 4 f) by a simple and green method using 3,5-di-tert-butyl-4-hydroxybenzoic acid (DT) and samarium chloride hexahydrate (SmCl 3 ·6H 2 O) via coordination reaction.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.

- Does a sustained release of EAB improve anti-oxidative capacity of rubber composites?

- Moreover, the retention of EAB for SBR/Loaded HNTs is about 50% higher than for SBR/HNTs and CDs after the thermo-aging testing, demonstrating the sustained release of CDs from HNTs could enhance the anti-oxidative capacity of the rubber composites.