6ppd (4020) Good Dispersibility Rubber Antioxidant

- Classification:Chemical Auxiliary Agent

- Purity:98%

- Type:Rubber additive antioxidant

- Appearance:Grey purple to purple brown pastilles

- Water Solubility:Insoluble in Water

- Application:rubber shoes and other rubber products

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

rubber antioxidants and chemical 6ppd,as one of the widespread rubber antioxidants, amine antioxidants (ppds: tmppd, dppd, 6ppd, and 6ppdtz) could react with o 3 (in parts per billion volume levels) in the environment and produce ppd-quinone .

application: 6ppd is suitable for rubber formulation of natural and synthetic rubber. it can be applied to tires, conveyor belts, hoses, cables, rubber dams, etc., which need dynamic and static antioxidant and ozone protection.

recent progress in the rubber antioxidants Rubber Auxiliary Agent

the authors claimed that the thermal aging resistance rubber compounds containing nr-g-ppdam were better than those containing low molecular weight antioxidant 6ppd.

rubber antioxidant 6ppd 4020 793-24-8 manufacturer,rubber antioxidant 6ppd is a high-performance antioxidant that is designed to protect rubber products from oxidative degradation caused by environmental factors such as heat, oxygen, and ozone. it is a dark purple-brown solid that is soluble in organic solvents and has a melting point of approximately 46-50℃.

rubber antioxidant 6ppd (4020) a must-have for improving

rubber antioxidant 6ppd (4020) is a highly efficient multi-purpose antioxidant with excellent antioxidant and high temperature resistance properties. it can significantly improve the durability and protective effect of rubber products, and is especially suitable for complex and harsh dynamic working conditions. .

6ppd rubber antioxidant: characteristics, applications,6ppd (n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a highly effective rubber antioxidant with notable characteristics, including excellent heat resistance, anti-flex cracking properties, and compatibility with various rubber types.

rubber antioxidant 4020(6ppd) with high quality

6ppd is a polluting antioxidant. in addition to having good anti oxygen effect, it also has the functions of anti ozone, anti bending and cracking, and inhibiting harmful metals such as copper and manganese. cas no. 793-24-8. formula.

rubber antioxidants and their transformation products,recently, it was reported that the rubber antioxidant n-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine (6ppd or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (twps).

overview of rubber antioxidant 6ppd (4020) 20mt price

this article discusses the application prospects of rubber antioxidant 6ppd (4020) in mechanical products, analyzes its anti-aging properties and advantages in improving product durability, and provides practical reference for industry practitioners.

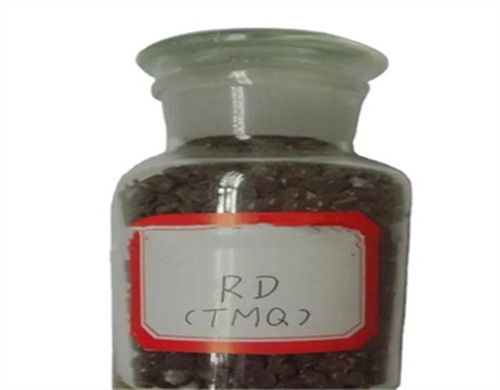

rubber antioxidants: tmq, 6ppd, ippd chemical products,tmq, also known as polymerized 2,2,4-trimethyl-1,2-dihydroquinoline, is a widely used rubber antioxidant. it provides excellent protection against heat, oxygen, and flex-cracking, enhancing the durability and performance of rubber products.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .

- Is carbon black a good reinforcing filler for rubber?

- Nonetheless, it is difficult to immobilize the antioxidants on the surface of carbon black, which historically and presently dominates the markets of reinforcing filler for rubber because of the lost cost and excellent reinforcing effect. 4.3. Controlled release of antioxidants from hollow filler

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.