technical data sheet

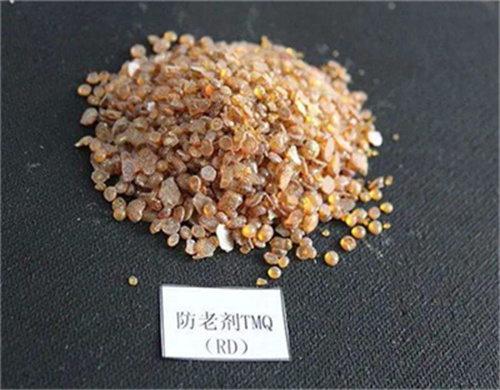

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Rubber chemicals

- Appearance:Amber to Brown Flake or Granular

- Melting point:72-94°C

- Application:Suitable for all kinds of tires and rubber

- Production Capacity:50000000t/Year

- Package:25 kg plastic woven bag

rubber antioxidant dtpd (3100) supplier,its performance of anti-ozone, anti-scratch and anti-cracking is far better than antioxidant a and d. dtpd has good long-term performance especially used with the antioxidant 4020 or 4010na 1:1. its greatly increased solubility in rubber and the much lower blooming allow a greater using amount. it has little influence on vulcanization and scorch.

trade name: antioxidant dtpd (3100) cas no: 68953-84-4 specification: item specification appearance brownish grey pastille initial melting point (dry) oc 90‐100 heating loss (65oc,3h) % ≤ 0.5 ash (800±25oc) % ≤ 0.3 main properties:

application of antioxidant dtpd/3100 in rubber industry

dtpd is suitable for natural rubber and various synthetic rubbers, such as styrene-butadiene rubber (sbr), butadiene rubber (br), chloroprene rubber (cr), etc. it can play an anti-aging role in various rubber products, including tires, hoses, seals, wires and cables, soles, etc.

Rubber Anti Aging Agent Rubber Antioxidant 6PPD 4020,its performance of anti-ozone, anti-scratch and anti-cracking is far better than antioxidant a and d. dtpd has good long-term performance especially used with the antioxidant 4020 or 4010na 1:1. its greatly increased solubility in rubber and the much lower blooming allow agreater using amount.

1ton rubber antioxidant dtpd (3100) price

rubber antioxidant dtpd (3100) chemical name: n,n'-ditolyl-p-phenylene diamine (mixture) other name: cas no.: it is equivalent to vulkanox 3100, wingstay 100. 68953-84-4 technical specification: item technical specifications appearance brownish

properties and uses of antioxidant dtpd (3100),the antioxidant dtpd protects tires and rubber products such as rubber pipes, conveyor belts, o-rings, sealing rings, gaskets and wipers for a long time. nature: appearance: dark brown particles molecular weight: 274 g / mol water solubility: insoluble organic solvent: soluble in acetone, toluene and xylene melting point: 87-105 degrees decomposition point: greater than 200 degrees purpose 1.

antioxidant dtpd(3100) chloropropyltriethoxysilane for sale

antioxidant dtpd(3100), which can be classified in p-phenlene antioxidant groups, is excellent antiozonant to chloprene rubber. it is the effective antioxidant used in the tyre industry and also widely used for rubber products. dtpd can resist ozone, its capacity to.

rubber antioxidant dtpd (3100) vennok,vestox dtpd is para phenylene diamine anti-aging agent, chloroprene adhesive antiozonidate. it is high efficient anti-aging agent in tyre industry and can also be applied to various rubber products. vestox dtpd is with good long-term performance especially when it is combined with antioxidant 6ppd (4020) or ippd (4010na), which is the best.

dtpd (3100) Chemical Product Antioxidant

antioxidant 4010na or 4020 provides short-time protection, but dtpd can provide long-term protection. 3. because of one or two solubilizing groups on the benzene rings in dtpd, the solubility in the rubber is enhanced highly and the bloom is reduced, so that a

antioxidant dtpd(3100) with high effective,antioxidant dtpd (3100), which can be classified in p-phenlene antioxidant groups. is excellent antioxidant to chloprene rubber. it is the effective antioxidant used in the tire industry and also widely used for rubber products.1.dtpd can resist ozone, its capacity to resist flexibility and cracking is similar to antioxidant 4010na or 4020.

- Are p phenylenediamine (PPD) antioxidants in recycled tire rubber products toxic?

- Recently, roadway releases of N, N ′-substituted p -phenylenediamine (PPD) antioxidants and their transformation products (TPs) received significant attention due to the highly toxic 6PPD-quinone. However, the occurrence of PPDs and TPs in recycled tire rubber products remains uncharacterized.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- What are the future trends of rubber antioxidants?

- The perspectives on the future trends of rubber antioxidants have been presented. Elastomers, especially diene-rubbers containing unsaturated double carbon bonds in the main chains, are vulnerable to thermal/oxygen aging, which would make the elastomers less elastic and result in earlier failure of the elastomer products.

- Are rubber antioxidants a rational design?

- The development of medical antioxidants also inspires the rational design of rubber antioxidants. Recently, Sun, et al. synthesized a novel antioxidant (APPT) containing aromatic amine, thiourea and allyl groups by the reaction between N-phenyl-p-phenylenediamine and allyl isothiocyanate (Fig. 3 b) .