Antioxidant IPPD Chemical Auxiliary Agent for Rubber Tyre-rubber accelerator rubber

- Classification:Chemical Auxiliary Agent

- Purity:95%

- Type:Anti-aging agent

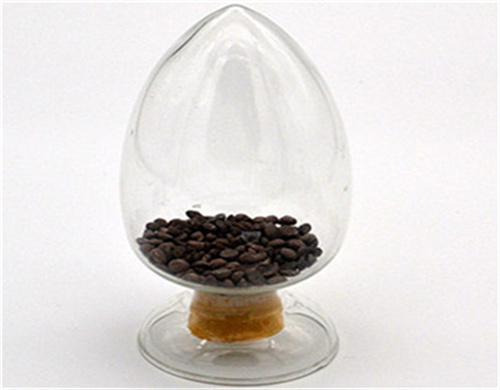

- Appearance:Grayish purple to purple brown granular

- Grade:Superior Class

- Application:used in manufacture of tires

- Production Capacity:100000 Metric Ton per Year

- Package:25kg/bag, OEM

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rd is a very important category rubber antioxidant. it has a good protective effect for heat, oxygen and fatigue aging, and stronger inhibitory effect for metal catalytic oxidation, no spray cream phenomenon, widely used in the manufacture of tyres, motorcycles tires, bicycles tires, rubber shoes, rubber tubes, rubber tape, wires cables and other rubber products.

rubber antioxidant tmq chemical products

antioxidant tmq is a widely used antioxidant, especially used in the rubber industry. similar to other antioxidants, tmq acts as an anti-aging agent and protects rubber from heat and heat. antioxidants are substances that hinder oxidation. antioxidants play a role.

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

environmental chemical rubber antioxidants

natural antioxidants are only found in nr, such as amino acids, tocotrienol, and betaines [], whereas physical and chemical antioxidants are widely used in various synthetic rubber products. the rubber-aging process comprises three stages: initiation, reaction, and termination [ 15 , 16 ], and the physical antioxidants are usually used to address the initiation stage of rubber aging.

rubber vulcanization accelerator tbbs (ns) rodon chem,boost rubber vulcanization with tbbs (ns) accelerator. our high-quality rubber chemical enhances performance and durability. order now! ns is also known as: n-tert-butyl-2-benzothiazolesulphenamide; accelerator ns; 2-(tert-butylaminothio)benzothiazole; n-tertiarybutyl-2-benzothiazole sulfennamide; tbbs; 2-[(tert-butylamino)sulfanyl]-1,3-benzothiazole; 2-benzothiazolesulfenamide, n-tert-butyl.

the ultimate guide to rubber accelerators in 2024 wellt

explore the comprehensive guide on rubber accelerators in 2024. learn about their classifications, applications, safety guidelines, and latest industry trends.

recent progress in the rubber antioxidants price,this review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. the oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism [1]. as shown in fig. This product is combustible, when storing and transporting, always pay attention to fireproof and damp proof.

rubber accelerator tbbs (ns) 95-31-8 manufacturer

rubber accelerator tbbs(ns); cas no. 95-31-8 ; molecular formula: c11h14n2s2; other synonyms: n-tert-butyl-2-benzothiazolesulfenamide get quote for your products or ask for solution for the compounds which you can’t find in the market. we are here to

(pdf) rubber antioxidants and their transformation products,antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-t rimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, account- ing for more than.

- Can polymerized TMQ reduce rubber oxidation?

- The addition of polymerizable antioxidants is one of the most preferable methods to overcome rubber oxidation [14, 15]. One of the mostly used antioxidants is polymerized TMQ. It is a secondary amine and can strongly inhibit the oxidation reactions of rubber [16, 17, 18].

- Is polymerized TMQ an antioxidant?

- One of the mostly used antioxidants is polymerized TMQ. It is a secondary amine and can strongly inhibit the oxidation reactions of rubber [16, 17, 18]. Zidan et al. prepared galloyl hydrazide and used it as antioxidant for natural rubber (NR).

- Do antioxidants and their TPS increase environmental risk awareness of rubber products?

- To our knowledge, this is the first review on antioxidants and their TPs in the environment, which may elevate the environmental risk awareness of rubber products and their TPs in the near future.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.