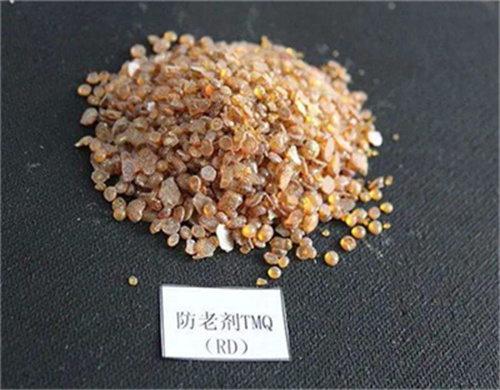

best selling rubber antioxidants tmq particles

- Classification:Chemical Auxiliary Agent

- Purity:96.9%

- Type:Anti-aging agent

- Appearance:Amber to Brown Flake

- Certificate:COA, MSDS, TDS

- Application:Paper Chemicals, Rubber Auxiliary Agents

- Storage:Dry and Cooling Place

- Package:1000kgs/ pallet with film

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-t rimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, account- ing for more than.

rubber chemicals antioxidant imports in bangladesh volza

according to volza's bangladesh import data, bangladesh imported 11 shipments of rubber chemicals antioxidant during sep 2022 to aug 2023 (ttm). these imports were supplied by 6 foreign exporters to 6 bangladesh buyers, marking a growth rate of 57% compared to the preceding twelve months.

rubber antioxidants and their transformation products,2. production and use of typical rubber antioxidants. rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . to date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for.

rubber antioxidants and their transformation products mdpi

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

rubber antioxidant 4020 request for factory price,this product is not suitable for making light-colored products due to serious pollution. antioxidant 4020 is one of the main varieties of p-phenylenediamine antioxidant. p-phenylenediamine antioxidant is the main good varieties commonly used in rubber industry at home and abroad, and it is also the development direction of antioxidant in the.

rubber aging agent 6ppd(4020) national standard quality

rubber aging agent 6ppd(4020) national standard quality rubber additives high efficiency anti aging. rubber antioxidant 4020/6ppd. chemical name:n-(1,3-dimethyl-buty)-n’-phenyl-p-phenylenediamine molecular: c18h24n2 cas no.: 793-24-8. molecular weight: 268.40. hs code: 3812301000

rubber antioxidant 4020 with low cost,applications include the use in pneumatic tire components, solid tires, belts, hoses, cable, automotive mounts, bushing and general mechanical products that are exposed to continuous and intermittent dynamic operating conditions and require protection from ozonation.

4020 6ppd antioxidant for tyre manufactures and rubber

also used as stablizer in synthetic rubber which is widely applied in many kinds of rubber products. rubber antioxidant 6ppd(4020) can be use for below tires: 1. passenger car tires

rubber antioxidant dtpd (3100) supplier,application: an antioxidant which is particularly good in neoprene.it can be used in tire industry as well as many other rubber products. its performance of anti-ozone, anti-scratch and anti-cracking is far better than antioxidant a and d. dtpd has good long-term performance especially used with the antioxidant 4020 or 4010na 1:1.

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- What is thermo-oxidative aging of rubber?

- This review mainly focused on thermo-oxidative aging because it is the most common aging type for rubbers. The oxidative degradation of rubber proceeds by a free-radical chain reaction mechanism . As shown in Fig. 1a, rubber aging processes have three distinct phases: (i) Initiation, (ii) Propagation, and

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.