Rubber Chemical Product Antioxidant Tmq/Rd

- Classification:Chemical Auxiliary Agent

- Purity:97%

- Type:Rubber chemicals

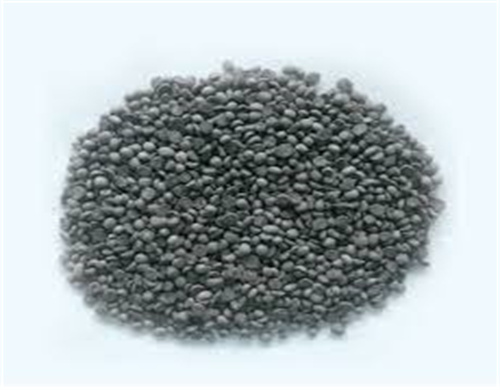

- Appearance:Grey to Very Dark Grey Solid

- Specification:Customized

- Application:Leather Auxiliary Agents

- Production Capacity:1000 Metric Tons per Month

- Package:20kg kraft bags,500kgs/pallet

rubber antioxidant tmq (rd) for tyre manufactures,contact us. get quote for your products or ask for solution for the compounds which you can’t find in the market. we are here to provide flexible service and contract manufacturing compound for you. rubber antioxidant tmq (rd); cas no. 26780-96-1 ; molecular formula: c12h15n; other synonyms: 2,2,4-trimethyl-1,2-dihydroquinoline.

This product is a pollution antioxidant and a high-performance general antioxidant among amine stabilizers. It has excellent antioxidant, ozone resistance, flex crack resistance, and sunlight crack resistance. It has a strong inhibitory effect on toxic metals such as copper or manganese and is suitable for all types of synthetic rubber and natural rubber.

best selling rubber antioxidants tmq particles

antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-t rimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, account- ing for more than.

rubber antioxidant tmq, tq, tdq, rd finorchem,rubber antioxidant tmq, tq, tdq, rd: it is a very important category of rubber antioxidants. it has a good powerful effect on heat, oxygen, and fatigue aging. 03340634254.

rubber antioxidants and their transformation products mdpi

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

production and use of typical rubber antioxidants,amine antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-trimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, accounting for more than 80% of the total amine antioxidants.

rubber antioxidant tmq(rd) (high-class) technical datasheet supplier

rubber antioxidant tmq(rd) (high-class) is suitable for tires, rubber tubes, gummed tapes, rubber overshoes and general industrial rubber products. read more view less download product type antioxidants chemical composition 2,2,4-trimethy1-1,2 26780-96.

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

synthesis of antioxidant for natural rubber using new heterogeneous

in this paper, a new type of heterogeneous catalytic system was devised for the synthesis of 4,4′-bis-(2,6-di-t-butylphenol), (hereinafter referred to as bisphenol-vn). the properties of the catalytic system were studied using sem–eds and transmission electron microscope methods. the results have demonstrated the presence of hydrophobic phenolate layer on the surface of the catalytic.

tmq-rd antioxidant for sale, tmq antioxidant price, tmq antioxidant,application: rd is a very important category rubber antioxidant. it has a good protective effect for heat, oxygen and fatigue aging, and stronger inhibitory effect for metal catalytic oxidation, no spray cream phenomenon, widely used in the manufacture of tyres , motorcycles births, bicycles births, rubber, plastic, adhesive tape, wires, cables and other rubber products.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Why do we need antioxidants for rubber composites?

- Therefore, for a real application, the antioxidants are indispensable to retard the thermal-oxidative-aging process of the rubber composites and then prolong the service life. In this review, we systematically review the recent progress of antioxidants for rubber.

- Can rubber antioxidants contain rare-earth ions?

- The recently reported rubber antioxidants containing rare-earth ions are summarized in Fig. 4, for instance, Sun et al. prepared a novel hindered phenol rare-earth complex (DTSm) (Fig. 4 f) by a simple and green method using 3,5-di-tert-butyl-4-hydroxybenzoic acid (DT) and samarium chloride hexahydrate (SmCl 3 ·6H 2 O) via coordination reaction.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.