tire manufacturers rubber antioxidant 6ppd

- Classification:Chemical Auxiliary Agent

- Purity:95.9%

- Type:Antioxidant

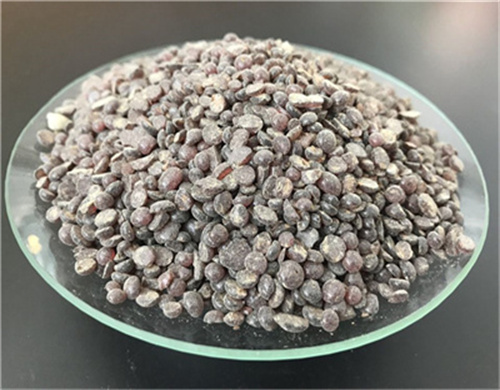

- Appearance:Dark purple granule

- Environmental Protection:Yes

- Application:Rubber Auxiliary Agents

- Storage:Cool Dry Place

- Package:25 kg/bag,1000 kg/bag,customized packaging

end-of-life tire decontamination from 6ppd and upcycling nature,abstract. n (1,3-dimethylbutyl)- n ′-phenyl- p-phenylenediamine (6ppd) is a ubiquitous rubber antioxidant and antiozonant that extends the lifetime of common rubber products, such as those.

washington d.c.—the push to find an alternative to the tire antidegradant 6ppd—an additive that is critical to consumer safety but can transform into an offshoot chemical that is fatal to some fish species—continues for the u.s. tire manufacturers association.

6ppd is recognised as a challenge tyre and rubber recycling

6ppd is an antioxidant and antiozonant that helps prevent the degradation and cracking of rubber compounds caused by exposure to oxygen, ozone and temperature fluctuation. 6ppd is used industry-wide to help tyres resist degradation and cracking, which is vital for driver and passenger safety. antioxidants support increased tyre endurance.

transformation products of tire rubber antioxidant 6ppd in,6ppd, a tire rubber antioxidant, poses substantial ecological risks because it can form a highly toxic quinone transformation product (tp), 6ppd-quinone (6ppdq), during exposure to gas-phase ozone. important data gaps exist regarding the structures, reaction mechanisms, and environmental occurrence of tps from 6ppd ozonation. to address these data gaps, gas-phase ozonation of 6ppd was.

6ppd: its role in tire manufacturing and environmental impact

published oct 19, 2024. 6ppd, or n- (1,3-dimethylbutyl)-n’-phenyl-p-phenylenediamine, is a chemical compound widely used in tire manufacturing. its primary function as an antioxidant enhances tire durability by preventing degradation from environmental factors like heat, oxygen, and ozone. however, recent studies have raised concerns about.

6ppd rubber antioxidant: characteristics, applications,6ppd (6ppd or n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a widely used rubber antioxidant that plays a vital role in the production of rubber products. this article aims to provide an overview of 6ppd, its characteristics, its applications in rubber product manufacturing, potential product combinations, and important considerations for commercial procurement. 1. what is 6ppd? 6ppd.

rubber antioxidants tmq particles with best selling

antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

6ppd in tire manufacturing ustma,6ppd: an essential ingredient for tire safety. safety is at the core of everything tire manufacturers do and the complex blend of rubber compounds and materials in our products is designed to withstand a wide range of demanding conditions. 6ppd serves an essential safety function in tires as an antioxidant and antiozonant, protecting the.

The latest development of rubber antioxidants

currently, rubber antioxidants are one of the indispensable additives in the rubber industry, they enhance the service life and reliability of the rubber product by protecting it from degradation. unfortunately, antioxidative efficiency, toxicity, and blooming/migration issues, etc., have plagued the development of rubber antioxidants.

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

- Is 6PPD in tires a priority product?

- DTSC designates 6PPD in tires as a Priority Product and USTMA expands its consortium to 32 tire manufacturers from around the world to prepare a Preliminary (Stage 1) Alternatives Analysis (AA) to identify and evaluate potential alternatives to 6PPD in tires. Individual consortium members submitted the report to DTSC to meet compliance deadline.

- Is there an alternative to 6PPD in tires?

- Today there is no commercially available alternative to 6PPD that both provides comparable safety and performance in motor vehicle tires and minimizes potential environmental effects. 6PPDQ Identified | USTMA requests DTSC review 6PPD in tires

- What causes 6ppd-q in soil and tire rubber wear particles (TRWPS)?

- There is a linkage between 6PPD-Q in soil and tire rubber wear particles (TRWPs), indicating its origin from sources associated with vehicular activities (Klockner et al., 2019). Approximately 50% of TRWPs can infiltrate the soil, releasing bound chemicals like 6PPD (Klockner et al., 2019).

- Can 6PPD be removed from end-of-life tires?

- We introduce a decontamination strategy that removes 6PPD from end-of-life tires before it enters the broader ecosystem. We demonstrate the catalytic upgrade of 6PPD to safe chemicals and the valorization of crumb rubber to aromatics and carbon black using microwave-assisted pyrolysis. You have full access to this article via your institution.