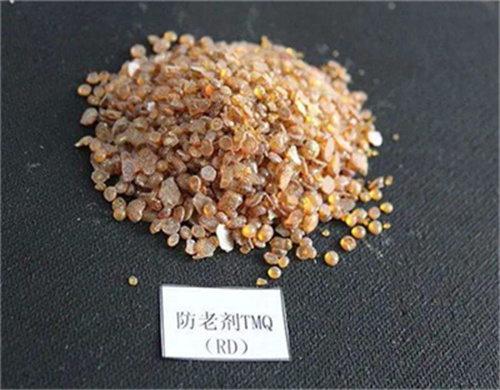

performance characteristics of rubber additives and its application price

- Classification:Chemical Auxiliary Agent

- Purity:98%

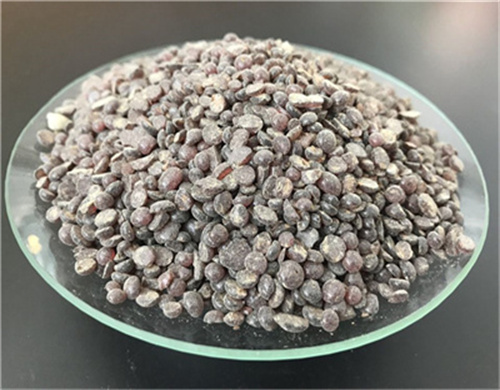

- Type:Anti-aging agent

- Appearance:Grey purple to purple brown pastilles

- MOQ:1 ton

- Application:used in manufacture of tires

- Production Capacity:10000tons/Year

- Package:25 Kgs/kraft bag

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

antioxidant 3100 has one or two compatibilizing genes introduced into the benzene ring on both sides of the molecular structure, so its solubility in rubber increases, the amount in rubber can be increased, and the application of antioxidants 4010na and the defect

rubber antioxidant 4020(6ppd) prospector by ul

access 3 properties in additives. create your free account or sign into prospector. processing find specific processing information for rubber antioxidant as well as general information for the additive -- antioxidant / heat stabilizer generic family. register or sign in for more information.

environmental chemical rubber antioxidants,2.1. amine antioxidants amine antioxidant is the most common rubber antioxidant, which was produced as early as the 1970s and widely used in the rubber industry. typical amine antioxidants include diaryl-secondary amine, acetone-amine condensation product, p-phenylenediamine, and aldehyde-amine condensation product antioxidants [].

screening p-phenylenediamine antioxidants, their transformation

recently, roadway releases of n,n′-substituted p-phenylenediamine (ppd) antioxidants and their transformation products (tps) received significant attention due to the highly toxic 6ppd-quinone. however, the occurrence of ppds and tps in recycled tire rubber products remains uncharacterized. here, we analyzed tire wear particles (twps), recycled rubber doormats, and turf-field crumb rubbers.

rubber aging agent 6ppd(4020) national standard quality rubber,detail introduction rubber antioxidant 4020/6ppd chemical name:n-(1,3-dimethyl-buty)-n’-phenyl-p-phenylenediamine molecular: c18h24n2 cas no.: 793-24-8 molecular weight: 268.40 hs code: 3812301000 as a kind of phenylene diamine rubber antioxidant.

rubber antioxidant 6ppd(4020) (high-class) henan rtenza supplier

find products that are predicted to be compatible with rubber antioxidant 6ppd(4020) (high-class). this list of compatible products is generated out of estimated hsp values. a practical determination of these hsp values would provide higher certainty. learn more.

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rubber antioxidant 6ppd 4020 with good price

rubber antioxidant 6ppd 4020 product name:ippd (4010 na)chemical name:n-isopropyl-n'-phenyl-p-phenylenediaminecas no.:793-24-8product specification:rubber antioxidant -phenyl-p-phenylenediamine4020 6ppdname:4020 6ppdcas no.793-24-8einecs

(pdf) rubber antioxidants and their transformation products,antioxidants are the main rubber antioxidants produced and used in china, of which 6ppd and 2,2,4-t rimethyl-1,2-dihydroquinoline (tmq, rd) have the highest production, account- ing for more than.

- What are rubber antioxidants?

- Rubber antioxidants are defined as substances that could delay the aging of polymer compounds and prolong the service life of rubber products by inhibiting oxidation, heat, or light radiation . To date, the annual global consumption of rubber antioxidants is over 700,000 tons, accounting for about 40% of the total amount of rubber additives.

- How does antioxidant 4020 affect m of nr/4020 composites?

- Also, the ΔM for NR/4020 composites decreases when increasing the loading of antioxidant 4020, which is most probably because antioxidant 4020 is a small molecule compound, which acts as a plasticizer and therefore decrease the torque. Similar phenomena were observed in the NR/CCDs composites.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.