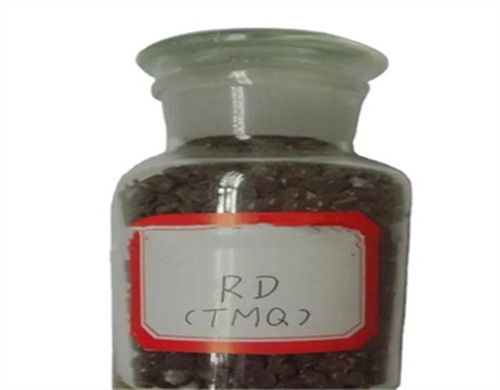

best rubber antioxidant ippd/4010na for tyre

- Classification:Chemical Auxiliary Agent

- Purity:97%

- Type:Rubber antioxidant

- Appearance:Grey to Very Dark Grey Solid

- Melting Point:45.0℃

- Application:For natural rubber

- Production Capacity:20000 Metric Ton/Metric Tons per Year

- Package:25 kgs per bag

rubber antioxidants: tmq, 6ppd, ippd price,antioxidant 6ppd (4020) 6ppd, or n-1,3-dimethylbutyl-n’-phenyl-p-phenylenediamine, is a synthetic rubber antioxidant widely used in the tire and rubber industry. it provides protection against degradation caused by heat, oxygen, and flex-cracking. 6ppd acts as a stabilizer and antiozonant, preventing the formation of harmful free radicals and.

product name: rubber antioxidant ippd cas no.: 101-72-4 mf: c15h18n2 einecs no.: 202-969-7 appearance: grayish purple to purple-brown granular

rubber antioxidant ippd(4010) chemical 101-72-4

rubber antioxidant ippd(4010) is dissolves in the oil class, the acetone, the benzene, the carbon tetrachloride carbon, the carbon bisulfide, and the ethyl alcohol, difficult to dissolve in the gasoline. if it is exposes under the air and the sunlight will change color.

recent progress in the rubber antioxidants price,the oxidation induction time (oit) test is shown in fig. 3 c, the oit value for the rubber sample with appt was 126.6 min, which was much longer than that of samples with antioxidant ppd or ippd. usually, the more resistant the rubber is to oxidative degradation, the longer the oit value is.

p-phenylenediamines and p-phenylenediamine quinone

according to data from the china rubber industry association, 6ppd and ippd have the highest production volumes among all rubber antioxidants (approximately 60% of the total), which explains the high contributions of 6ppd and ippd in the dust samples (china rubber industry association, 2023). in residential environments, ippd, dnpd, and 6ppd-q.

rubber antioxidant ippd (4010na) (high-class) henan rtenza,it acts as an antioxidant. it is suitable for natural rubber and synthetic rubber especially for the prevention of thermal deterioration on nbr. it provides high temperature and flexing resistance. rubber antioxidant ippd(4010na) (high-class) is recommended for use in tire components.

6ppd rubber antioxidant: characteristics, applications

6ppd (6ppd or n-(1,3-dimethylbutyl)-n'-phenyl-p-phenylenediamine) is a widely used rubber antioxidant that plays a vital role in the production of rubber products. this article aims to provide an overview of 6ppd, its characteristics, its applications in rubber product manufacturing, potential product combinations, and important considerations for commercial procurement. 1. what is 6ppd? 6ppd.

rubber antioxidants and their transformation products mdpi,antioxidants are prevalently used during rubber production to improve rubber performance, delay aging, and extend service life. however, recent studies have revealed that their transformation products (tps) could adversely affect environmental organisms and even lead to environmental events, which led to great public concern about environmental occurrence and potential impacts of rubber.

rubber antioxidant ippd: enhancing competitiveness in the

rubber antioxidant ippd (n-isopropyl-n'-phenyl-p-phenylenediamine), as a key chemical additive, is widely used in the rubber industry, especially in the production of automobiles, tires and seals. improve aging resistance. thanks to its unique molecular structure, ippd can effectively inhibit oxidation reactions and significantly extend the.

N(1,3-dimethyl-butyl)-N'-phenyl-P-phenylenediamine chemical active antioxidant,infobox references. n-isopropyl-n′-phenyl-1,4-phenylenediamine (often abbreviated ippd) is an organic compound commonly used as an antiozonant in rubbers. [1] like other p-phenylenediamine -based antiozonants it works by virtue of its low ionization energy, which allows it to react with ozone faster than ozone will react with rubber. [2]

- Are p phenylenediamine (PPD) antioxidants in recycled tire rubber products toxic?

- Recently, roadway releases of N, N ′-substituted p -phenylenediamine (PPD) antioxidants and their transformation products (TPs) received significant attention due to the highly toxic 6PPD-quinone. However, the occurrence of PPDs and TPs in recycled tire rubber products remains uncharacterized.

- Which industrial rubber additives have higher chemical concentrations?

- Furthermore, we quantified 15 other industrial rubber additives (including bonding agents, vulcanization accelerators, benzotriazole and benzothiazole derivatives, and diphenylamine antioxidants), observing that PPD-derived chemical concentrations were 0.5–6 times higher than these often-studied additives.

- How does a rubber matrix affect antioxidative performance?

- Obviously, the solubility/dispersity of the antioxidant within the rubber matrix is a key factor in determining the antioxidative performance, and the antioxidative efficiency of antioxidant increases with the dispersion state within the rubber matrix, owing to higher specific surface area available for termination of radicals.

- Can a rubber antioxidant enter the environment with tire-wear particles (Twps)?

- Recently, it was reported that the rubber antioxidant N - (1,3-dimethylbutyl)- N′ -phenyl- p -phenylenediamine (6PPD or antioxidant 4020), a typical tire rubber antioxidant, could enter the surrounding environment together with tire-wear particles (TWPs) [7, 8].