technical data sheet

- Classification:Chemical Auxiliary Agent

- Purity:96.9%

- Type:Antioxidant

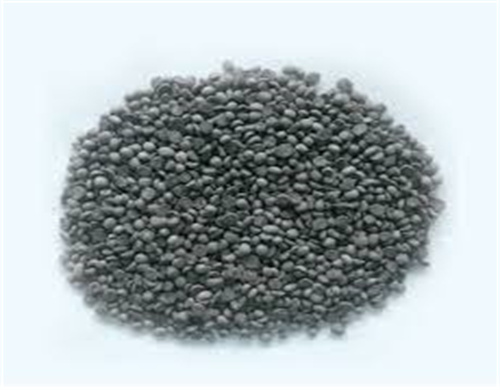

- Appearance:Amber to Brown Granulose

- Specification:Customized

- Application:Leather Auxiliary Agents

- Production Capacity:100000 Metric Ton per Year

- Package:25kg/bag, OEM

advantages of rubber antioxidant ippd in tropical regions,explore the benefits of rubber antioxidant ippd in enhancing the durability and market competitiveness of rubber products in tropical climates. learn how ippd can extend the service life of rubber and improve product resistance to aging.

ene adhesive antiozonidate. it is high efficient anti-aging agent in tyre industry and can also be applied to various rubber products. ozone-proof, anti-flexibility and crazing resistant performance of anti-aging a gent dtpd is similar to those of the 6ppd and ippd and is much better than a nti-aging agent.

rubber anti-aging agent 6ppd and its ozonation product 6ppdq

rubber anti-aging agent 6ppd and its ozonation product 6ppdq: environmental distribution and biological toxicity li jia-yao, shen hui-min, xu ting-ting, guo ying guangdong key laboratory of environmental pollution and health, school of environment, jinan university, guangzhou 510632, china

recent progress in the rubber antioxidants price,in this review, we summarized the recent advances in rubber antioxidants over the last 10 years and offered some perspectives to outline the challenges and future research directions for the rubber antioxidants. 2. brief introduction of the oxidation process and oxidation mechanism of the rubbers.

rubber antioxidants and their transformation products

the rubber-aging process comprises three stages: initiation, reaction, and termination [15,16], and the physical antioxidants are usually used to address the initiation stage of rubber aging. a film-isolating oxygen and o 3 is formed on the surface of rubber products by directly applying or spraying, which can prevent the rubber from aging. by.

facrory supply anti-aging agent, tmq, 6ppd, ippd,it includes the most important type of anti-aging agent, and it is also a promising anti-aging agent. there are: anti-aging agent 4010na/ippd, anti-aging agent 4020/6ppd, anti-aging agent 4010/cppd, anti-aging agent oda, anti-aging agent dppd, anti-aging agent 7ppd, anti-aging agent 6ppd, anti-aging agent 3100/dtpd, anti-aging agent 445.

technical data sheet

ene adhesive antiozonidate. it is high efficient anti-aging agent in tyre industry and can also be applied to various rubber products. ozone-proof, anti-flexibility and crazing resistant performance of anti-aging a gent dtpd is similar to those of the 6ppd and ippd and is much better than a nti-aging agent.

biomass antioxidant silica supported tea polyphenols with,the phenomenon of rubber aging is inevitable. hence, for delaying the aging process and prolong the service life of rubber composites, appropriate commercial anti-aging agents are commonly added to the rubber products to achieve the performance of anti-aging [7, 8]. amine and phenolic antioxidants derived from petrochemical products such as.

premium rubber antioxidant rubber anti aging agent ippd/4010

it is supplying high-quality rubber chemical raw materials such as natural rubber, synthetic rubber, accelerator, antioxidant, zinc oxide, stearic acid, carbon black, silan coupling agent, etc., with the certifications like reach, rohs,nsf, sgs, iso, etc.. and we have our own cnas lab.

biomass antioxidant silica supported tea polyphenols with,to achieve simultaneous environment protecting, high-efficiency rubber antioxidant is still an enormous and long-term challenge in green rubber industry. hence, a novel biomass antioxidant (denoted as silica-s-tp) was obtained by silica supported with green tea polyphenols exhibited prominent anti-aging functionality.

- Does antioxidant 2246 protect rubber from aging?

- Among them, antioxidant 2246 has a good performance to protect rubber from aging caused by heat, oxygen, and metals. Because hydrogen in phenolic antioxidants can combine with the oxygen in air, their antiaging efficiency is therefore lowered compared with amine antioxidants [21, 22].

- What are the TPS of rubber antioxidants?

- The TPs of rubber antioxidants have been observed in some studies under environmental conditions. As one of the widespread rubber antioxidants, amine antioxidants (PPDs: TMPPD, DPPD, 6PPD, and 6PPDTZ) could react with O 3 (in parts per billion volume levels) in the environment and produce PPD-quinone .

- What are amine antioxidants in rubber?

- Amine antioxidant is the most common rubber antioxidant, which was produced as early as the 1970s and widely used in the rubber industry. Typical amine antioxidants include diaryl-secondary amine, acetone-amine condensation product, p -phenylenediamine, and aldehyde-amine condensation product antioxidants .

- Which antioxidants are used in rubber vulcanization?

- The amine and phenolic antioxidants are the most widely used rubber antioxidants (Fig. 1 b and c). Generally, the phenolic antioxidants have poor antioxidative efficiency (compared to amine antioxidants) and they can delay vulcanization, but they cause little discoloration problems.